Appendix 1. Cable and Connector Specifications

A1 - 2

Appendix 1-1 Selection of cable

Appendix 1-1-1 Cable wire and assembly

(1) Cable wire

The following shows the specifications and processing of the wire used in each cable. Manufacture

the cable using the following recommended wire or equivalent parts.

Wire characteristics Recommended

wire model

(Cannot be directly

ordered from

Mitsubishi

Electric Corp.)

Finished

outside

diameter

Sheath

material

No. of

pairs

Config-

uration

Conductor

resistance

Withstand

voltage

Insulation

resistance

Heat

resistant

temperature

Applica-

tion

UL20276 AWG28

10pair

6.1mm PVC 10

7

strands/

0.13mm

222Ω/km

or less

AC350/ 1min

1MΩ/km

or more

80°C

NC unit

communi-

cation cable

A14B2343 (Note 1) 7.2mm PVC 6

40

strands/

0.08mm

105Ω/km

or less

AC500/ 1min

1500MΩ/k

m or more

105°C

Detector

cable

2

(0.3 mm

2

)

60

strands/

0.08mm

63Ω/km

or less

TS-91026 (Note 2) 11.6mm PVC

10

(0.2 mm

2

)

40

strands/

0.08mm

95Ω/km

or less

AC750V/

1min

60MΩ/km

or more

60°C

Detector

cable

(Cable length:

20m or more)

(Note 1) Junko Co. (Dealer: Toa Denki)

(Note 2) BANDO ELECTRIC WIRE (http: //www.bew.co.jp)

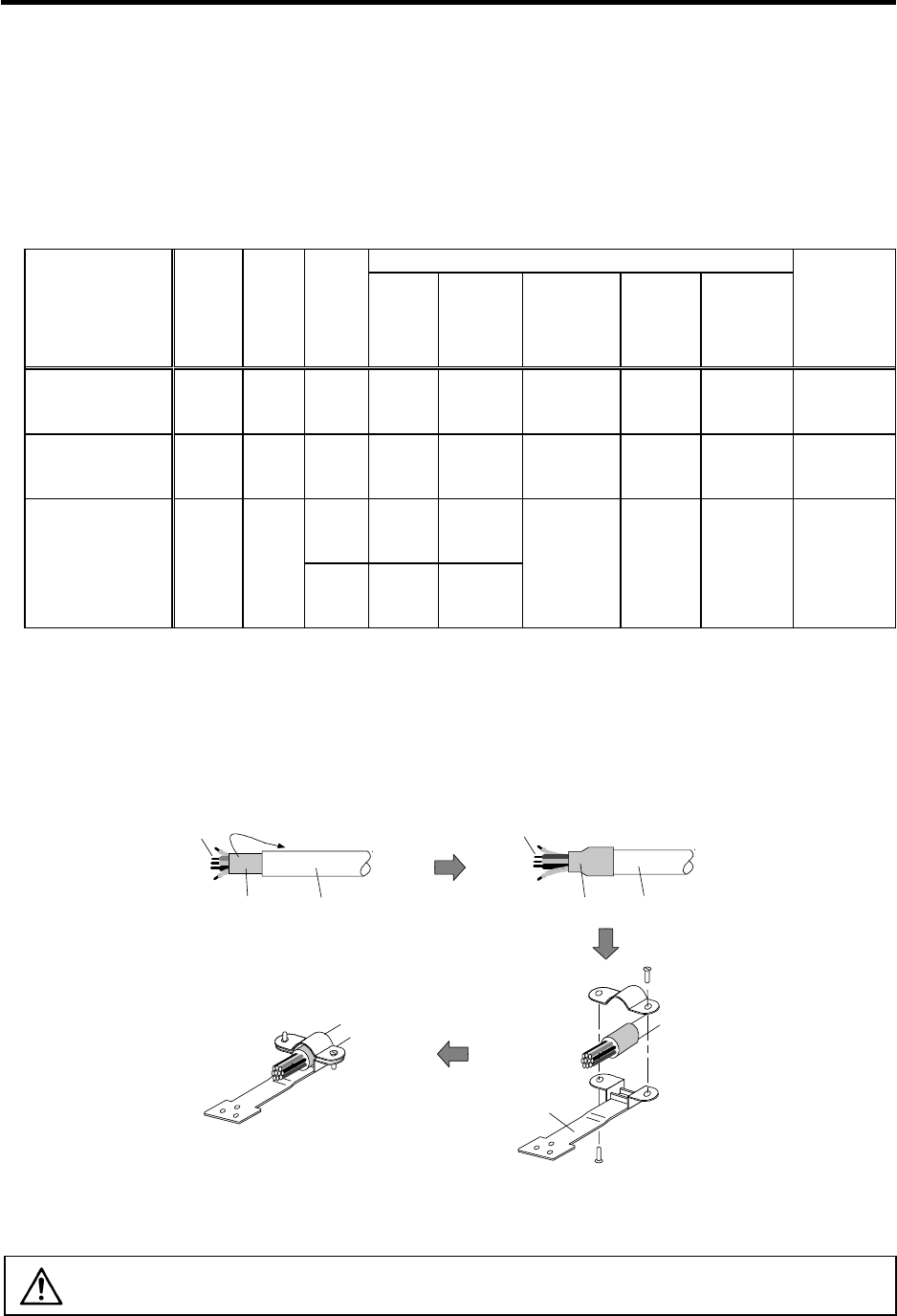

(2) Cable assembly

Assemble the cable as shown in the following drawing, with the cable shield wire securely

connected to the ground plate of the connector.

Ground plate

Shield

(external conductor)

Sheath

Shield

(external conductor)

Sheath

Core wire

Core wire

CAUTION

Do not mistake the connection when manufacturing the detector cable. Failure to

observe this could lead to faults, runaway or fires.