4. Servo Adjustment

4 - 5

No. Abbrev. Parameter name Explanation Setting range

SV005 VGN1 Speed loop gain 1

Set the speed loop gain.

Set this according to the load inertia size.

The higher the setting value is, the more accurate the control will be,

however, vibration tends to occur.

If vibration occurs, adjust by lowering by 20 to 30%.

1 to 999

POINT

The final VGN1 setting value is 70 to 80% of the maximum value at which the

machine does not resonate.

Suppressing the resonance with the vibration suppression function and increasing

the VGN1 setting is effective for adjusting the servo later.

(2) Setting the speed loop lead compensation

The speed loop lead compensation (SV008: VIA) determines the characteristics of the speed loop

mainly at low frequency regions. 1364 is set as a standard, and 1900 is set as a standard during

SHG control. The standard value may drop in respect to loads with a large inertia.

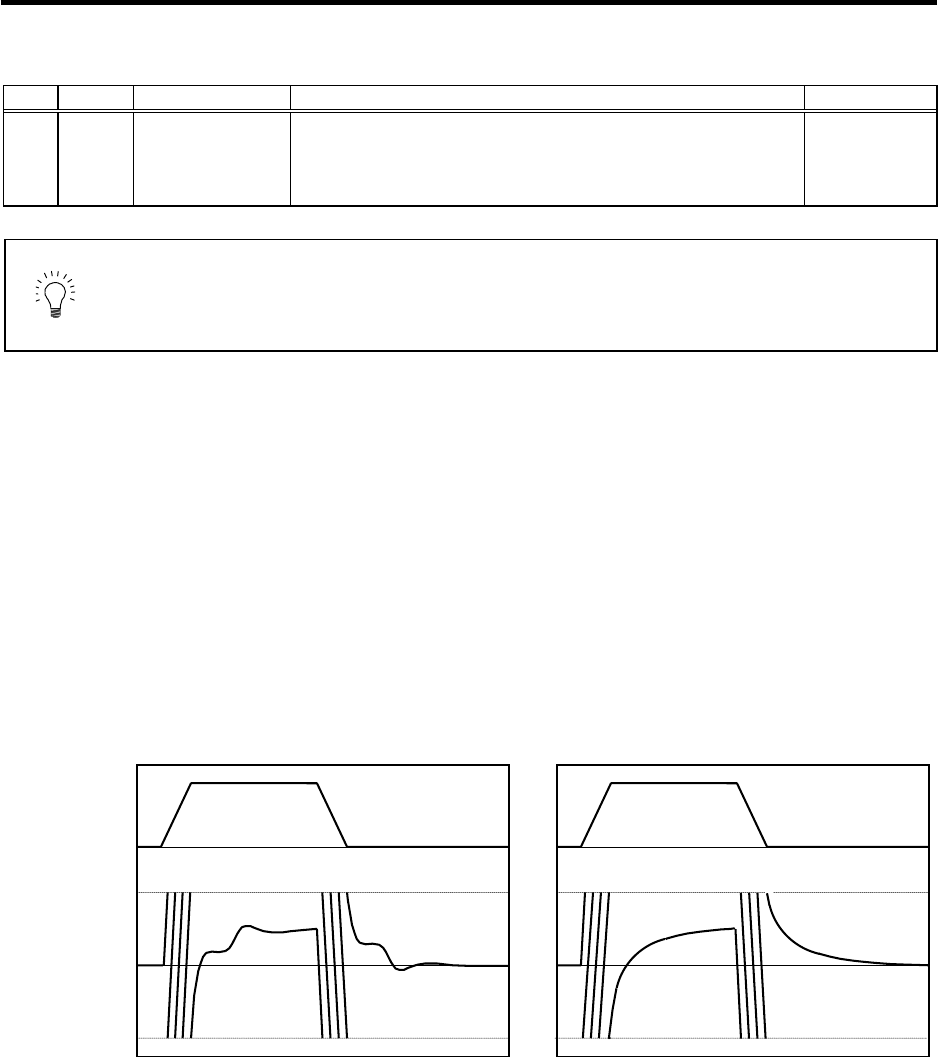

When the VGN1 is set lower than the standard value because the load inertia is large or because

machine resonance occurred, the speed loop control band is lowered. If the standard value is set

in the leading compensation in this status, the leading compensation control itself will induce

vibration. In concrete terms, a vibration of 10 to 20Hz could be caused during acceleration/

deceleration or stopping, and the position droop waveform could be disturbed when accelerating to

a constant speed and when stopped. (Refer to lower left drawing)

This vibration cannot be suppressed by the vibration suppression functions. Lower the VIA in

increments of 100 from the standard setting value. Set a value where vibration does not occur and

the position droop waveform converges smoothly. Because lowering the VIA causes a drop in the

position control's trackability, the vibration suppression is improved even when a disturbance

observer is used without lowering the VIA. (Be careful of machine resonance occurrence at this

time.)

If VIA is lowered, the position droop waveform becomes smooth and overshooting does not occur.

However, because the trackability in respect to the position commands becomes worse, the

positioning time and accuracy are sacrificed. VIA must be kept high (set the standard value) to

guarantee precision, especially in high-speed contour cutting (generally F = 1000 or higher). In other

words, in a machine aiming for high speed and high accuracy, a large enough value must be set in

VGN1 so that VIA does not need to be lowered. When adjusting, the cutting precision will be better if

adjustment is carried out to a degree where overshooting does not occur and a high VIA is

maintained, without pursuing position droop smoothness.

Vibration waveform with lead compensation control Adjusted position droop waveform

0

0

Speed FB

Position

droop

0

0

Time

D/A output range

Time

Time

Time