6. Troubleshooting

6 - 47

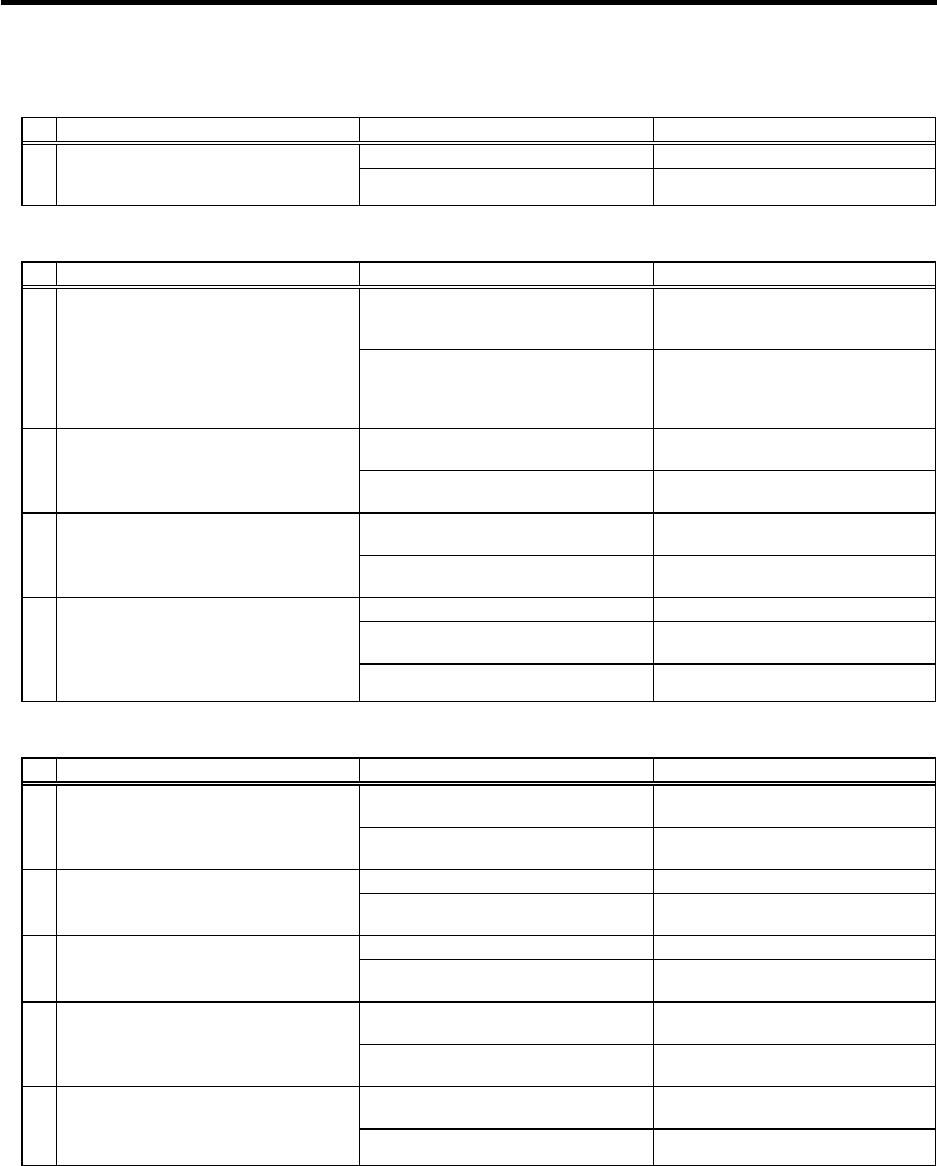

[7] The spindle coasts during deceleration.

Investigation item Investigation results Remedies

There is slipping. Repair the machine side.

1

Check whether there is slipping between

the motor and spindle. (When connected

with a belt or clutch.)

No particular problems found. Replace the drive unit.

[8] The rotation does not stabilize.

Investigation item Investigation results Remedies

The rotation stabilizes when the settings

values are both set to approx. double.

Change the setting value.

Note that the gear noise may

increase.

1

Check the spindle parameter settings.

(SP022, SP023)

The symptoms do not change even

when the above value is set.

Return the setting values to the

original values.

Investigate investigation item 2 and

remedy.

The connector is disconnected (or

loose).

Correctly connect the connector.

2

Tug on the connector by hand to check

whether the speed detector connector

(spindle drive unit side and speed

detector side) is loose.

The connector is not disconnected (or

loose).

Investigate investigation item 3 and

remedy.

The connection is faulty or

disconnected.

Replace the detector cable.

Correct the connection.

3

Turn the power OFF, and check the

connection of the speed detector cable

with a tester.

(Especially check the shield wiring.)

The connection is normal.

Investigate investigation item 4 and

remedy.

The grounding is incomplete. Correctly ground.

The alarm occurs easily when a specific

device operates.

Use noise measures on the device

described on the left.

4

Investigate the wiring and installation

environment.

• Is the ground correctly connected?

• Are there any noise-generating devices

near the drive unit?

No particular problems found. Replace the drive unit.

[9] The speed does not rise above a set level.

Investigation item Investigation results Remedies

The speed command is not input

correctly.

Input the correct speed command.

1

Check the speed command.

Check whether the override input is input

from the machine operation panel.

The speed command is input correctly.

Investigate investigation item 2 and

remedy.

The load has become heavier. Repair the machine side.

2

Check whether the load has suddenly

become heavier.

No particular problems found.

Investigate investigation item 3 and

remedy.

The bearings do not rotate smoothly. Replace the spindle motor.

3

Manually rotate the motor bearings and

check the movement.

The bearings rotate smoothly.

Investigate investigation item 4 and

remedy.

The connector is disconnected (or

loose).

Correctly connect the connector.

4

Tug on the connector by hand to check

whether the speed detector connector

(spindle drive unit side and speed

detector side) is loose.

The connector is not disconnected (or

loose).

Investigate investigation item 5 and

remedy.

The connection is faulty or

disconnected.

Replace the detector cable.

Correct the connection.

5

Turn the power OFF, and check the

connection of the speed detector cable

with a tester.

(Especially check the shield wiring.)

The waveform is normal. Replace the spindle drive unit.