4. Servo Adjustment

4 - 32

<Adjustment methods>

[1] Confirm that the motor end circle accuracy measured with the NC sampling function is

appropriate.

[2] In this state, measure the tool end low-speed and high-speed circle path without tool end

compensation. The difference of the high-speed circle path and low-speed circle path is the

amount that path has swelled due to the spring effect of the machine system. Calculate the

SV065 setting value with the following expression using this amount as the compensation

amount.

SV065 =

Compensation amount [µm] × radius R [mm] ×10

9

(command speed F [mm/min])

2

[3] Set SV027/bit7 to 1, and input the value calculated in step 2 into SV065. Measure the

high-speed circle path. If the shape is still elliptical, adjust by increasing/decreasing the SV065

value in 1/10 units.

[4] Confirm that there is no problem with the low-speed circle path.

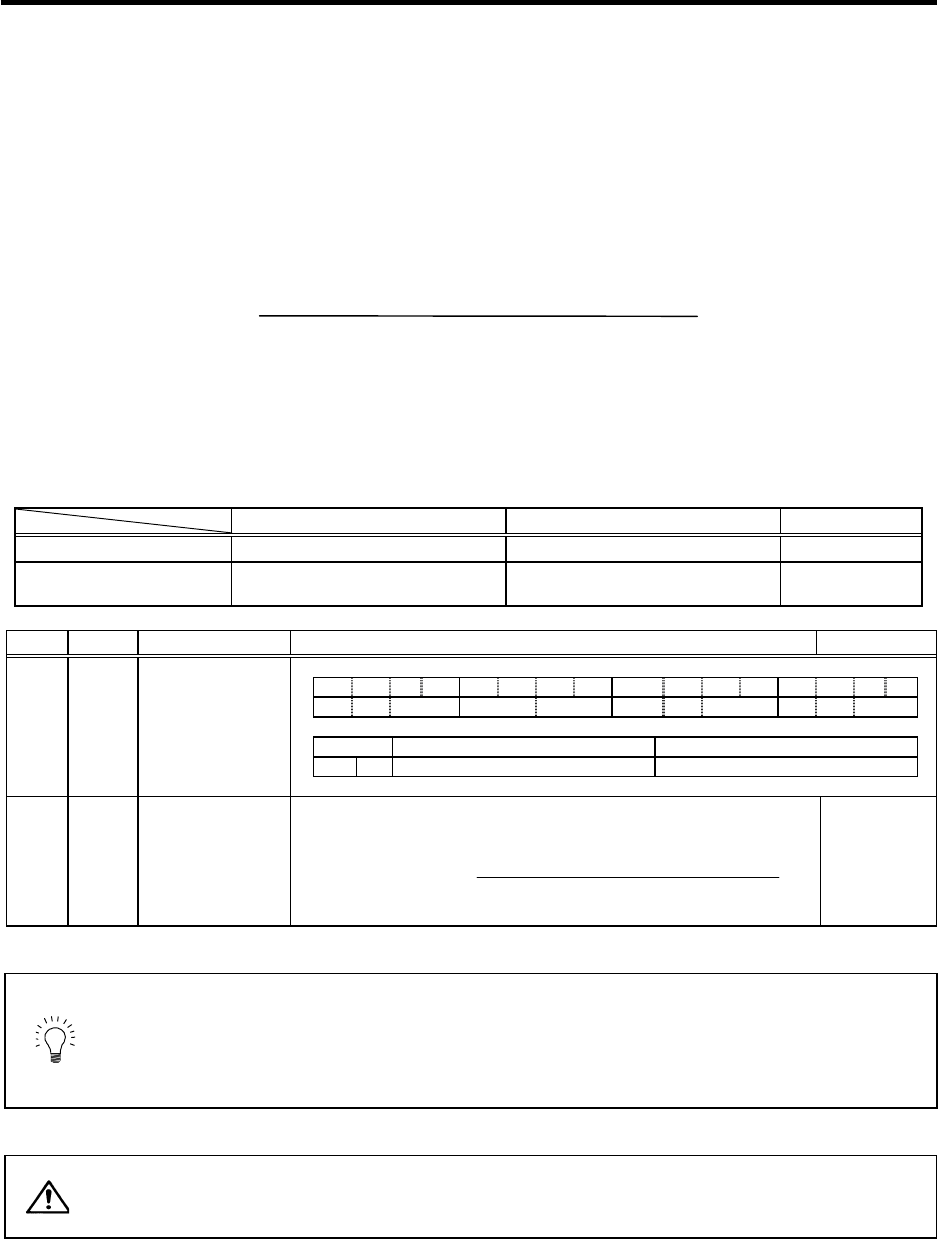

Example of low-speed and high-speed roundness measurement for adjusting tool end compensation

When using grid encoder When using DBB measurement Acceleration

Low speed (reference circle) R=25 [mm], F=500 [mm/min] R=100 [mm], F=1000 [mm/min] 0.00028G

High-speed (when adjusting

compensation amount)

R=25 [mm], F=10000 [mm/min] R=100 [mm], F=20000 [mm/min] 0.11G

No. Abbrev. Parameter name Explanation Setting range

SV027 SSF1 Servo function

selection 1 F E D C B A 9 8 7 6 5 4 3 2 1 0

aflt zrn2 afse ovs lmc omr zrn3 vfct upc vcnt

bit Meaning when "0" is set Meaning when "1" is set

7 omr Tool end compensation invalid Tool end compensation valid

SV065 TLC Tool end

compensation spring

constant

Set the spring constant of the tool end compensation.

In the semi-closed loop control, the tool end compensation amount is

calculated with the following equation.

Compensation amount =

Commanded speed F (mm/min)

2

×

SV065

Radius R (mm)

×

10

9

(µm)

When not using, set to "0".

-32768 to

32767

POINT

1. To confirm the machine's spring element, adjust the electrical end

roundness, and then tool end roundness while changing the cutting speed.

Confirm that the error increases with the speed.

2. The electrical end roundness will have an error on the inner side when tool

end compensation is used.

CAUTION

If an excessive value is set in the tool end compensation spring constant

(SV065), the machine could vibrate when stopping, resulting in a dangerous

state.