1. Installation

1 - 16

1-4 Installing the spindle detector

1-4-1 Magnetic sensor

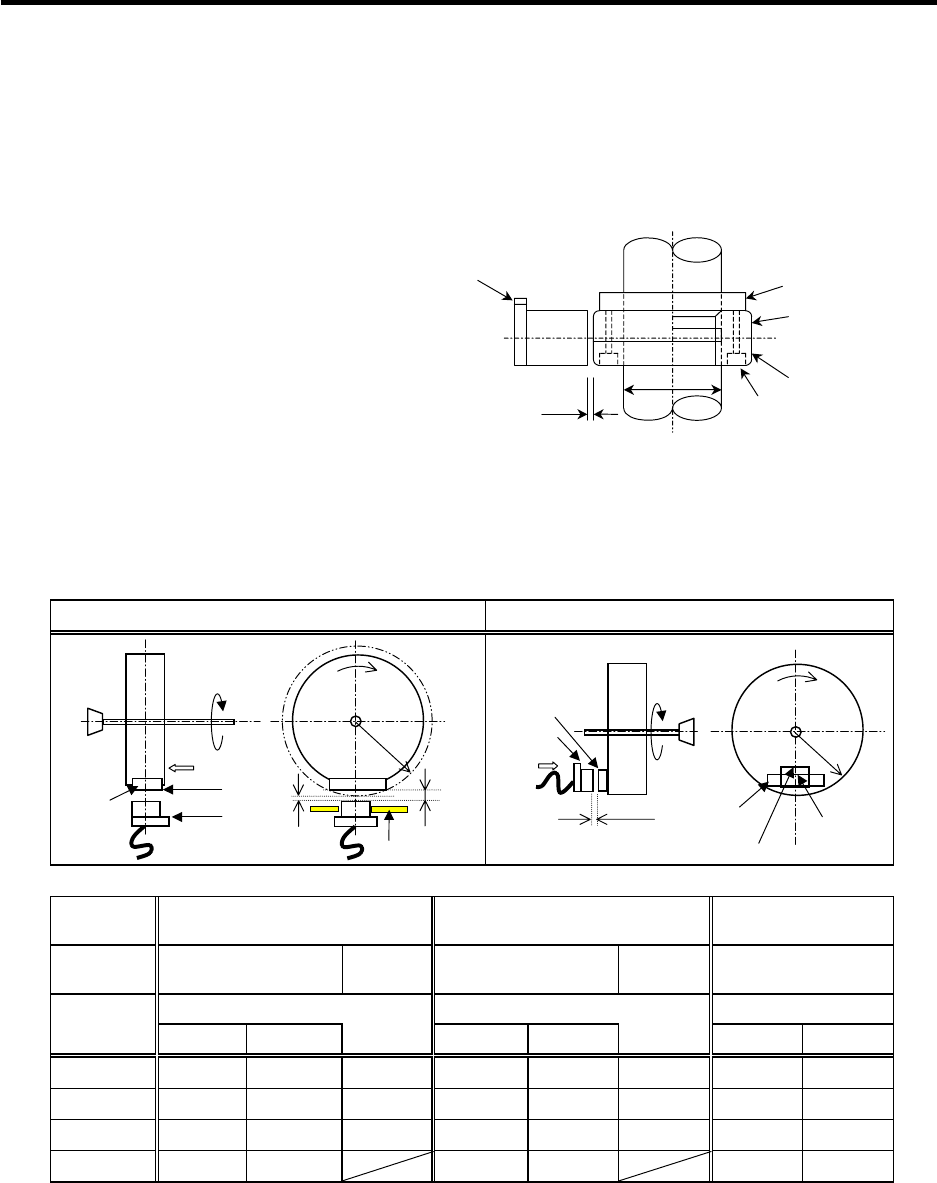

(1) Installing the magnetic sensor

• Tolerance to shaft dimension should

be "h6" on the part for installing a

magnet.

• 2-øG hole can be used for positioning

of spindle and magnet.

• Magnet shall be installed as shown to

the right.

• Misalignment between sensor head

and magnetic center line shall be

within ±2mm.

• There is an NS indication on the side of

the cover. Install so that the reference

notch on the sensor head comes to the

case side.

Gap

Reference notch

Reference drawing for magnet installation

G hole

h6

Spindle

Case

Cover

Spindle damping scre

w

(2) Gap between magnet and sensor

Circumference installation

Horizontal installation

Magnet

model

BKO-C1810H03 BKO-C1730H06 BKO-C1730H09

Installation

direction

Circumference

installation

Horizontal

installation

Circumference

installation

Horizontal

installation

Circumference

installation

Gap mm Gap mm Gap mm

R (Radius)

mm

Max. value Min. value Max. value Min. value Max. value Min. value

40 11.5±0.5 2.7±0.5 6.0±0.5 10.0±0.5 1.22±0.5 5.0±0.5 6.25±0.5 3.30±0.5

50 9.5±0.5 2.8±0.5 6.0±0.5 8.0±0.5 1.31±0.5 5.0±0.5 6.00±0.5 3.70±0.5

60 8.5±0.5 3.0±0.5 6.0±0.5 7.0±0.5 1.50±0.5 5.0±0.5 5.75±0.5 3.85±0.5

70 8.0±0.5 3.4±0.5 7.0±0.5 2.38±0.5 5.50±0.5 3.87±0.5

Reference

hole

Reference

notch

Magnet

Min. gap

Max. gap

Mounting plate

R

Direction of

rotation

NS

Spindle

Face A

Face A

Magnet

Gap

R

N

S

Spindle

Face B

Face B

Reference

hole

Reference

hole

Reference

notch

Direction of

rotation

Reference

notch