3. Setup

3 - 65

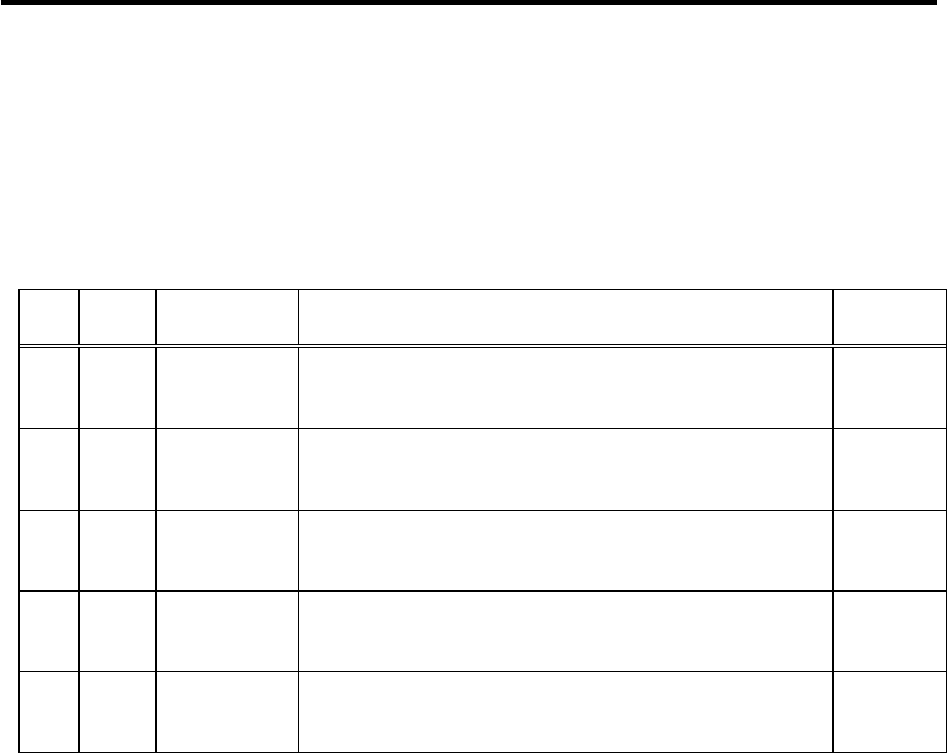

3-5 Setting the initial parameters for the spindle drive unit

The spindle specification parameters and spindle parameters must be set before the spindle system

can be started up. The spindle related parameters are input from the NC. The input method differs

according to the NC being used, so refer to each NC Instruction Manual.

3-5-1 Spindle specification parameters

The configuration of these parameters depends on the NC, so refer to each NC Instruction Manual. The

following table shows the configuration of the M60S and E60 Series NC.

M60S

Series

No.

Abbrev. Parameter name Details

Setting range

(Unit)

3001

3002

3003

3004

slimit 1

2

3

4

Limit rotation

speed

Set spindle rotation speed for maximum motor rotation speed with gears

00, 01, 10, 11.

(Set the spindle speed for the S analog output 10V.)

0 to 99999

(r/min)

3005

3006

3007

3008

smax 1

2

3

4

Maximum rotation

speed

Set maximum spindle rotation speed with gears 00, 01, 10, 11.

Set to slimt ≥ smax.

By comparing the S command value and the value of gear 1 to 4, a spindle

gear shift command will be output automatically.

0 to 99999

(r/min)

3009

3010

3011

3012

ssift 1

2

3

4

Shift rotation

speed

Set spindle speed for gear shifting with gears 00, 01, 10, 11.

(Note) Setting too large value may cause a gear nicks when changing

gears.

0 to 32767

(r/min)

3013

3014

3015

3016

stap 1

2

3

4

Tap rotation speed

Set maximum spindle rotation speed during tap cycle with gears 00, 01,

10, 11.

0 to 99999

(r/min)

3017

3018

3019

3020

stapt 1

2

3

4

Tap time constant

Set time constants for constant inclination synchronous tap cycles for

gears 00, 01, 10, 11 (linear acceleration/deceleration pattern).

1 to 5000 (ms)