1. Installation

1 - 20

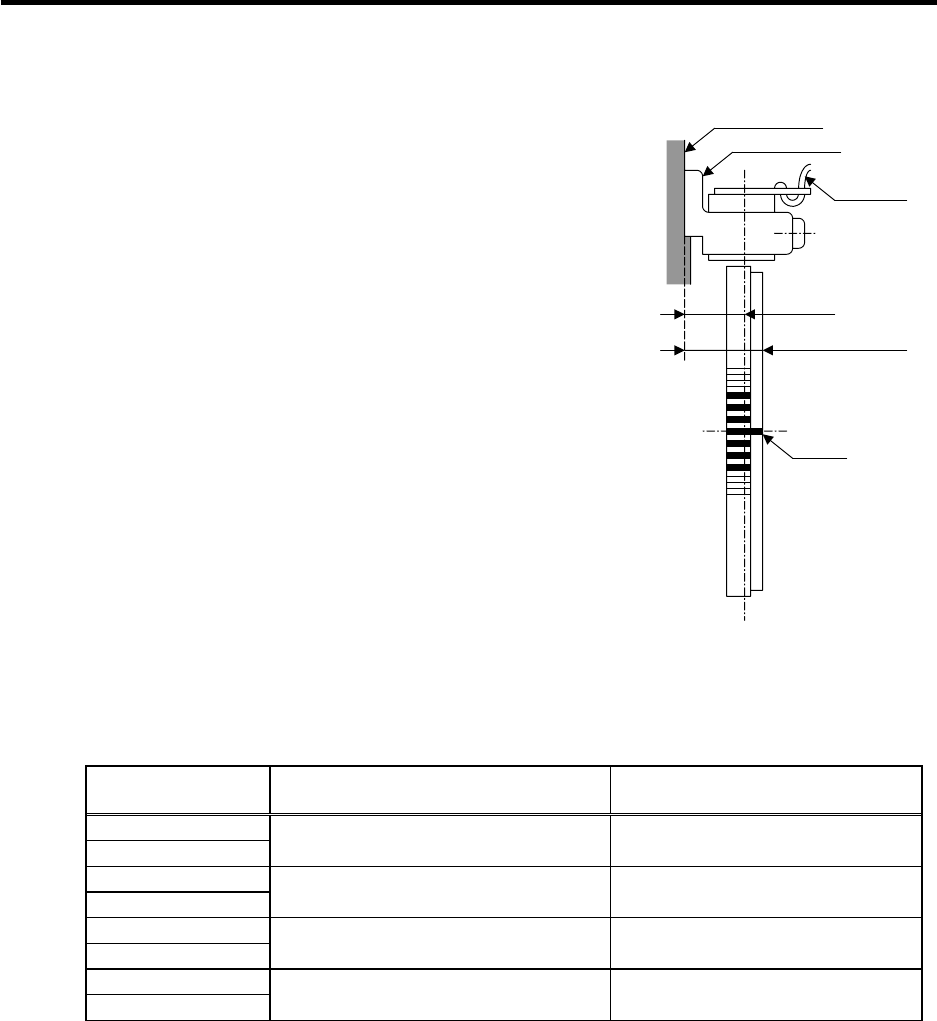

[3] Keep the deviation of the sensor center and detection

gear center to ±0.25mm or less. If the center deviation

cannot be directly measured, set so that the dimension

from the sensor installing surface to the edge of the

detection gears is 22.5±0.25mm.

[4] Keep the deflection of the outer diameter, when the

detection gears are installed on the shaft, to 0.02mm or

less.

[5] To remove a detection gear fixed with shrinkage fitting,

use the screw holes opened in the axial direction for

pulling (two M5 screw holes or two M8 screw holes), or

push the end with a jig. Carry out this work carefully.

Applying excessive force when pulling out the gears

could cause the inner diameter of the detection gears to

deform.

[6] Before reusing detection gears which have been

removed, always measure the inner diameter dimensions,

and carefully check that the inner diameter is not

deformed, and that the sufficient tightening amount can

be secured. Do not reuse the detection gears if the inner

diameter is deformed, or if any abnormality such as

damage to the teeth is found.

[7] A notched fitting section and mounting screw hole are

provided on the machine as shown in the following

drawing. Contact the R section of the sensor installation

seat against this and, install the sensor. The outline dimensions of the notched fitting section

are shown in the following table.

Installing the sensor section

Encoder part type

Sensor installation seat's

R dimensions (mm)

Notched fitting section's

outer diameter (mm)

TS1860N2275 +0.200

TS1860N2276

R35.5 ø71

+0.180

TS1860N2777 +0.200

TS1860N2775

R45 ø90

+0.180

TS1860N2171 +0.200

TS1860N2174

R61 ø122

+0.175

TS1860N2571 +0.200

TS1860N2572

R112.5 ø225

+0.170

16.5mm

22.5mm

±.25mm

Sensor installation surface

Sensor installation seat

Lead wire

First tooth

Installing the detection gears