3. Setup

3 - 86

No. Abbr. Parameter name Details

Setting range

(Unit)

Standard

setting

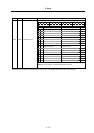

< For MDS-C1-SPH>

Set the minimum value of variable torque limit at

acceleration.

0 to 150

(%)

0

SP085 AIQM*

Target value of variable

torque limit magnification

at acceleration

< For MDS-C1-SP/SPX/SPHX/SPM >

Not used. Set "0".

0 0

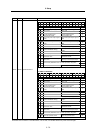

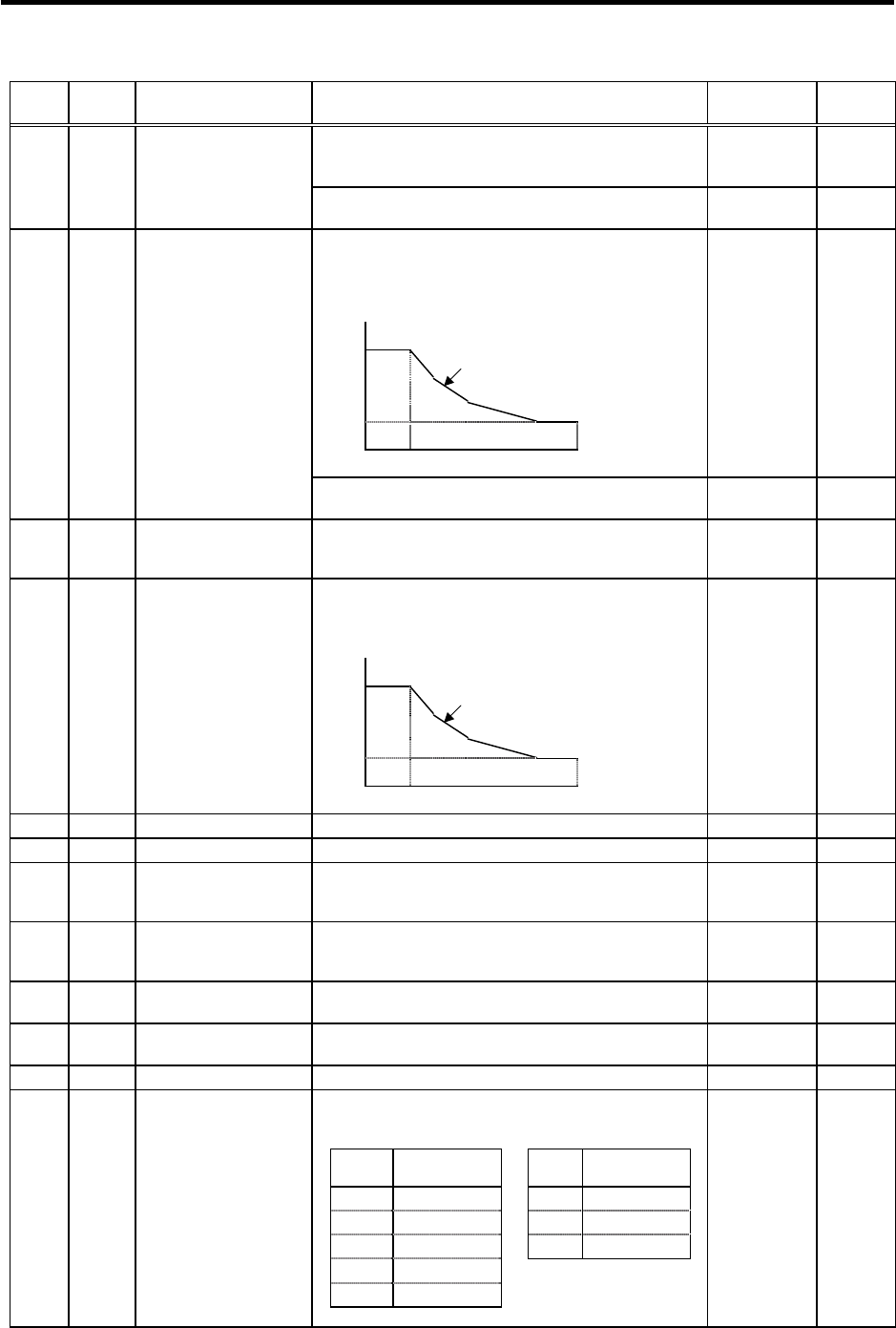

<For MDS-C1-SPH>

Set the speed where the torque limit value at acceleration

starts to change.

Torque limit

100%

SP085

SP086 SP017 Speed

0 to 32767

(r/min)

0

SP086 AIQN*

Speed for starting

change of variable

torque limit magnification

at acceleration

< For MDS-C1-SP/SPX/SPHX/SPM>

Not used. Set "0".

0 0

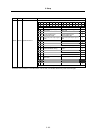

SP087 DIQM*

Target value of variable

torque limit magnification

at deceleration

Set the minimum value of variable torque limit at

deceleration.

0 to 150 (%) 75

Set the speed where the torque limit value at deceleration

starts to change.

Torque limit

SP088 DIQN*

Speed for starting

change of variable

torque limit magnification

at deceleration

100%

SP087

SP088 SP017 Speed

0 to 32767

(r/min)

3000

SP089 Not used. Set "0". 0 0

SP090 Not used. Set "0". 0 0

SP091 OFSN

Offset compensation

during motor PLG

forward run

Set the PLG offset for forward run.

Normally "0" is set.

-2048 to 2047

(-1mV)

0

SP092 OFSI

Offset compensation

during motor PLG

reverse run

Set the PLG offset for reverse run.

Normally "0" is set.

-2048 to 2047

(-1mV)

0

SP093 ORE*

Tolerable pulse check

error

Set this when detecting the pulse detector's pulse

mistakes. (Valid only for full close control.)

0 to 32767 0

SP094 LMAV* Load meter output filter

Set the filter time constant of load meter output.

When "0" is set, a filter time constant is set to 100ms.

0 to 32767

(2ms)

0

SP095 VFAV* Fixed control constant Set by Mitsubishi. Set "0" unless designated in particular. 0 0

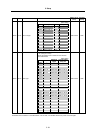

Set the gear ratio between the spindle end and the

detector end (except for the motor PLG) as indicated

below.

Setting

value

Gear ratio

(deceleration)

Setting

value

Gear ratio

(acceleration)

0 1 : 1 -1 1 : 2

1 1 : 1/2 -2 1 : 4

2 1 : 1/4 -3 1 : 3

3 1 : 1/8

4 1 : 1/16

SP096 EGAR* Encoder gear ratio

-3 to 4 0

Parameters with an asterisk * in the abbreviation, such as OSP*, are validated with the NC power turned ON again.

Inversely proportional to speed

Inversely proportional to speed