5. Spindle Adjustment

5 - 52

(4) Adjusting the parameters

Adjust the following parameters while measuring the synchronous error between the servo and

spindle. The servo axis speed loop gain is valid for all control, so adjust the speed loop gain only

on the spindle side. Adjust mainly the lost motion compensation parameters on the servo side.

When these have already been adjusted when measuring the roundness, etc., they do not need to

be adjusted again. If the acceleration/deceleration is delayed for one of the axes, set the

acceleration feed forward gain for the delayed axis to compensate the synchronous delay.

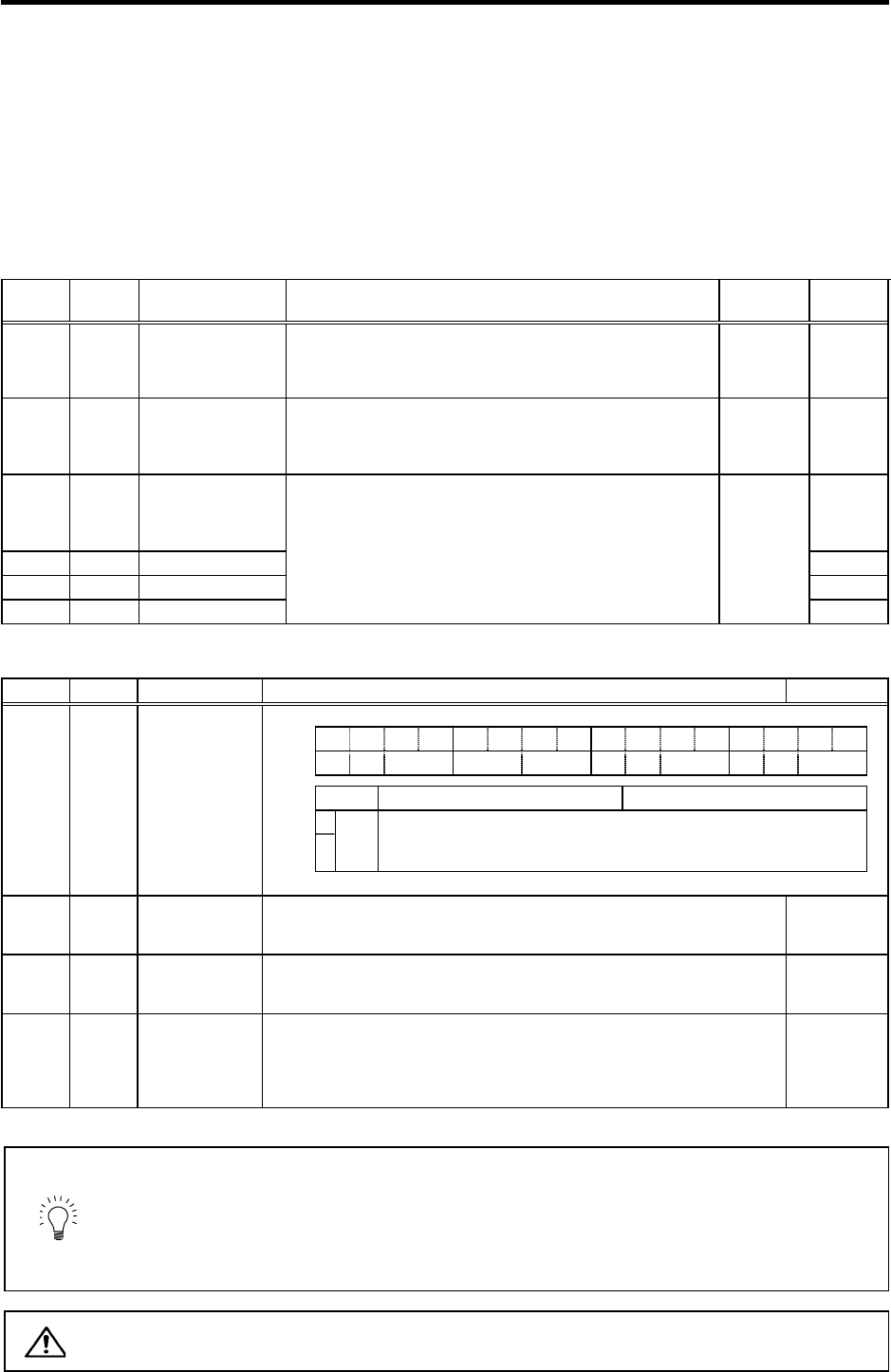

Spindle adjustment parameters

No. Abbr. Parameter name Details

Setting

range

Standard

SP194 VGTP* Synchronized

tapping control

speed loop gain

proportional term

Set the speed loop proportional gain in synchronized tapping

mode.

0 to 1000 63

SP195 VGTI* Synchronized

tapping control

speed loop gain

integral term

Set the speed loop integral gain in synchronized tapping mode.

0 to 1000 60

SP200 FFCI* Synchronized

tapping control

acceleration feed

forward gain (gear 1)

0

SP201 FFC2* (Gear 2) 0

SP202 FFC3* (Gear 3) 0

SP203 FFC4* (Gear 4)

Set the acceleration feed forward gain for selection of gear 000

during synchronized tapping.

This parameter should be used when an error of relative

position to Z-axis servo is large.

0 to 1000

(%)

0

Spindle adjustment parameters

No. Abbr. Parameter name Details Setting range

FEDCBA98765 4 3 2 10

aflt zrn2 afse ovs lmc omr zrn3 vfct upc vcnt

bit Meaning when set to 0 Meaning when set to 1

8

Set the compensation amount with SV016 (LMC1) and SV041 (LMC2).

9

lmc

00: Lost motion compensation stop

01: Lost motion compensation type 1

10: Lost motion compensation type 2

11: Setting prohibited

SV027 SSF1 Servo function

selection 1

SV016 LMC1 Lost motion

compensation 1

Set the compensation amount based on the stall (rated) current of the motor.

The standard setting is double of the friction torque. Setting to "0" means the

compensation amount is zero.

-1 to 200

(Stall [rated]

current %)

SV041 LMC2 Lost motion

compensation 2

Set this with SV016 (LMC1) only when you wish to set the lost motion

compensation amount to be different depending on the command directions.

Normally, set to "0".

-1 to 200

(Stall [rated]

current %)

SV015 FFC Acceleration rate

feed forward gain

When a relative error in the synchronous control is large, apply this parameter

to the axis that is delaying. The standard setting value is "0". For the SHG

control, set to "100".

To adjust a relative error in acceleration/deceleration, increase the value by

50 to 100 at a time.

0 to 999

(%)

POINT

1. Stop the machine error compensation function (backlash compensation,

pitch error compensation, etc.) when measuring the synchronous error.

2. The servo's speed loop gain has an effect on all control, so do not adjust it

for synchronous tap. The spindle parameters are dedicated for synchronous

tap control, so improve the synchronization accuracy by adjusting the spindle

parameters when possible.

CAUTION

The above spindle parameters adjusted when adjusting the synchronous tap

are all validated when the NC power is turned ON again.