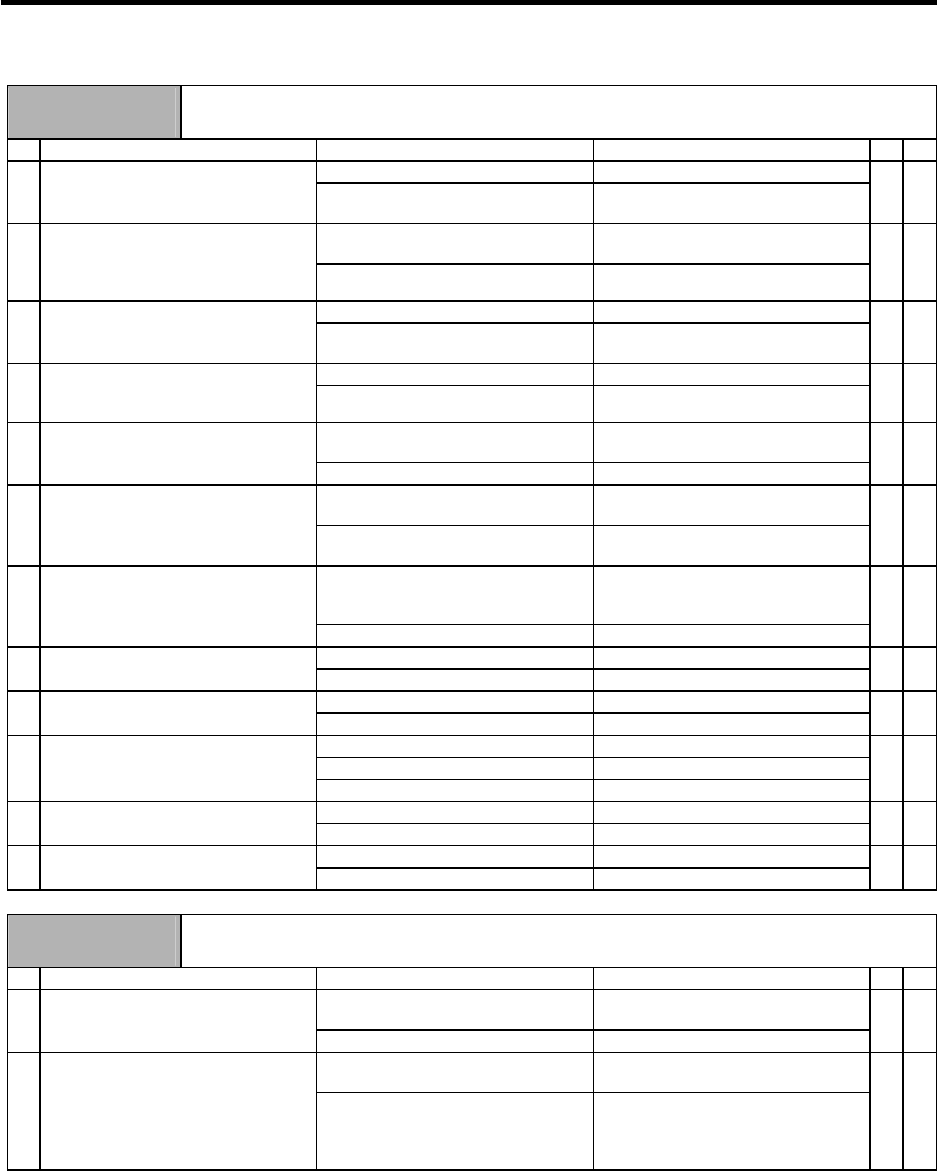

6. Troubleshooting

6 - 25

Alarm No.

46

Motor overheat

The temperature protection function in the motor or detector activated.

Investigation details Investigation results Remedies SV SP

The alarm occurs before operation. Investigate item 2. 1 Check the repeatability.

The alarm occurs occasionally after

operation is started.

Investigate item 5.

{ {

The connector is disconnected (or

loose).

Correctly install. 2 Check whether the drive unit

connectors (servo: CN3, spindle:

CN6) or detector connectors are

disconnected.

The connector is not disconnected. Investigate item 3.

{ {

The cable is broken. Replace the cable. 3 Using a tester, check whether the

detector cable is broken.

The cable is not broken. Servo : Investigate item 4.

Spindle : Investigate item 12.

{ {

SV034/bit2 = 0 Set SP034/bit2 to 1. 4 When using MDS-B-HR, is the motor

thermal validated even when it is not

provided?

SV034/bit2 = 1 Investigate item 12.

{

The load is large. Servo : Investigate item 6.

Spindle : Investigate item 8.

5 Check the overload % (servo) or load

meter (spindle).

The load is not large. Investigate item 9.

{ {

The constant load torque (friction +

unbalance) is 60% or more.

Select the motor so that the constant

load torque is 60% or less.

6 Is the unbalance torque high?

The constant load torque is less than

60%.

Investigate item 7.

{

The alarm was forcibly reset. Do not turn the drive unit's power

OFF when an overload alarm occurs.

(The NC power can be turned OFF.)

7 Was the overload alarm (50) forcibly

reset by turning the drive unit power

OFF?

The alarm was not forcibly reset. Investigate item 9.

{

There was an incorrect setting. Correctly set. 8 Check the parameter settings.

The settings are correct. Investigate item 9.

{

Hot. Investigate item 10. 9 Measure the motor temperature

when the alarm occurs.

Not hot. Investigate item 12.

{ {

The fan motor was stopped. Investigate item 11.

The motor fan wind flow is poor. Clean.

10 When using a motor with fan, check

whether the fan is stopped, or

whether it is clogged with dust, etc.

There is no problem. Investigate item 12.

{ {

The cable is broken. Replace the cable. 11 Check the fan wiring.

The cable is not broken. Replace the fan.

{ {

Improved. Replace the drive unit. 12 Try replacing the drive unit.

Not improved. Replace the motor.

{ {

Alarm No.

4E

NC command mode error

A spindle control mode selection outside the specifications was input.

Investigation details Investigation results Remedies SV SP

The alarm always occurs at the same

position.

Check the NC and PLC program

process.

1 Pinpoint where the alarm occurs in

the PLC program.

The alarm occurs irregularly. Investigate item 2.

{

The alarm occurs during position

control.

Check the NC and PLC program

process.

2 Does the alarm occur when position

control (C-axis, spindle

synchronization, synchronous tap) is

started?

The alarm occurs during speed

control.

Check the NC and PLC program

process.

(If the cause cannot be pinpointed,

replace the drive unit, and confirm.)

{