6. Troubleshooting

6 - 20

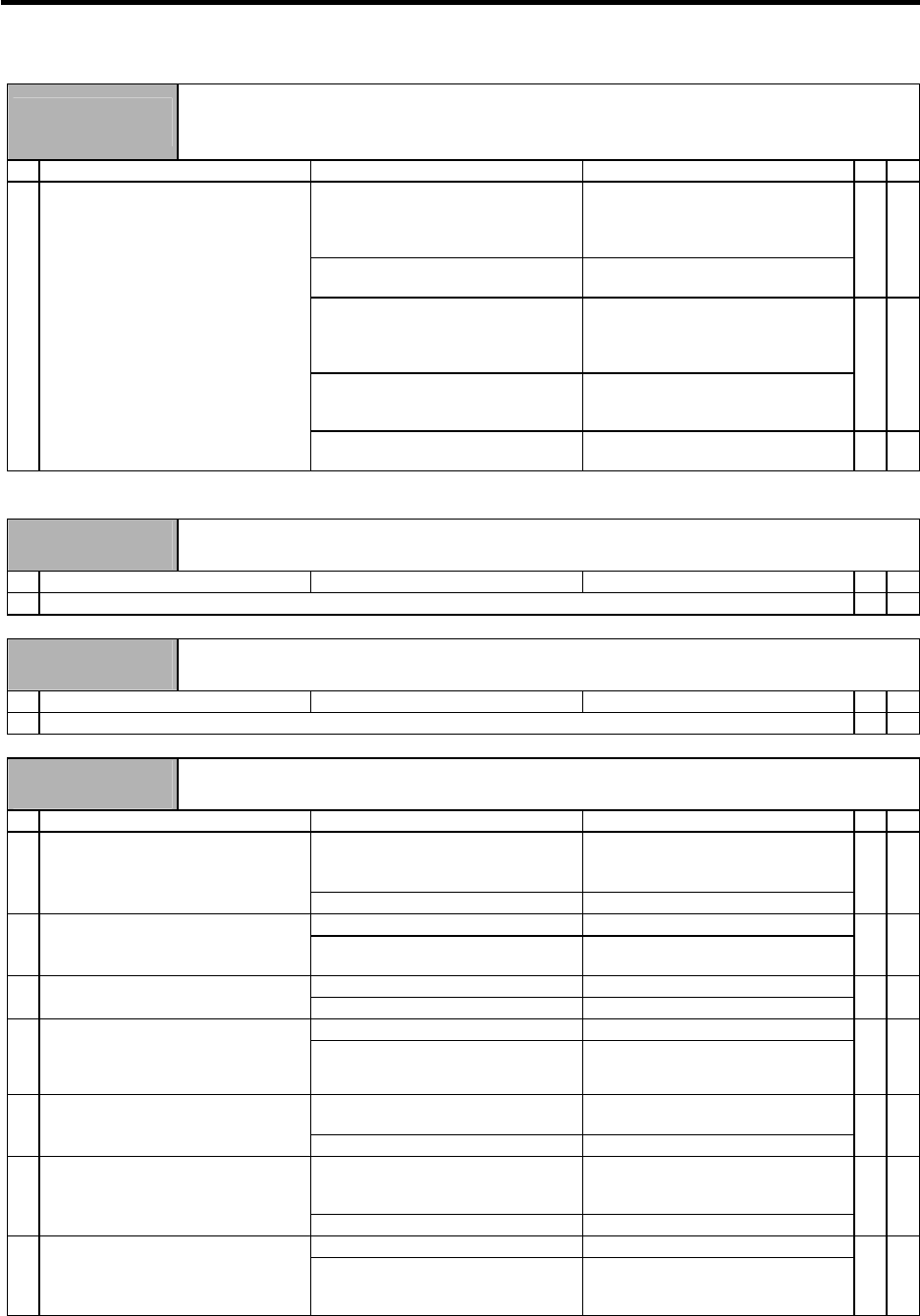

Alarm No.

37

Initial parameter error

An illegal parameter was detected in the parameters received from the NC at NC power ON.

"S02 initial parameter error ####" is displayed on the NC screen. #### indicates the incorrect

parameter No.

Investigation details Investigation results Remedies SV SP

SV001 to SV065 (M60S Series: 2201

to 2265)

SP001 to SP384 (M60S Series: 3201

to 3584)

Set the value within the designated

setting range.

1 Check the error parameter No.

SV101 (M60S Series: 2301)

The electronic gears are overflowing.

Check SV001, SV002 and SV018.

{ {

SV102 (M60S Series: 2302)

The absolute position detection

parameter is valid when OSE104 and

OSE105 are connected.

Absolute position control cannot be

used. To use, change to an absolute

position detector.

SV104 (M60S Series: 2304)

No SHG control operation is

provided.

SHG control cannot be used.

{

SV105 (M60S Series: 2305)

No adaptive filter option is provided.

The adaptive filter cannot be used.

{

(Note) Refer to "6-3-4 Parameter numbers at initial parameter error".

Alarm No.

38

Communication or protocol error 1 between NC and drive unit

An error was detected in the communication frame received from the NC.

Investigation details Investigation results Remedies SV SP

1 Check the alarm No. "34" items.

{ {

Alarm No.

39

Communication or protocol error 2 between NC and drive unit

An error was detected in the axis information data received from the NC.

Investigation details Investigation results Remedies SV SP

1 Check the alarm No. "34" items.

{ {

Alarm No.

3A

Overcurrent

An excessive current was detected in the motor drive current.

Investigation details Investigation results Remedies SV SP

Vibration is occurring.

• Set a filter.

• Lower the speed loop gain

(SV005).

1 Check whether vibration is occurring.

There is no vibration. Investigate item 2.

{

The setting is too large. Set an appropriate value. 2 The speed loop gain (SV005) setting

is larger than the standard value.

The setting is approximately the

same as the standard value.

Investigate item 3.

{

The setting is incorrect. Set the standard value. 3 Check the current loop gain.

(SV009, SV010, SV011, SV012)

The standard value is set. Investigate item 4.

{

The power cable is short-circuited. Replace the motor power cable. 4 Disconnect the UVW phase wiring

from the terminal block, and the

cannon plug from the motor. Check

the insulation with a tester.

There is no problem. Investigate item 5.

{

There is a ground fault at the power

cable.

Replace the motor power cable. 5 Check the insulation between the

motor power cable and FG.

There is no problem. Investigate item 6.

{

There is a ground fault in the motor. Replace the motor.

(With the absolute position system,

the zero point must be established.)

6 Connect the cannon plug, and check

the insulation between the power

cable and FG.

There is no problem. Investigate item 7.

{

No abnormality is found in particular. Replace the drive unit. 7 Check if there is any abnormality in

the motor's ambient environment.

(Ex. Ambient temperature, cutting

water)

An abnormality was found in the

ambient environment.

Improve the installation environment.

(With the absolute position system,

the zero point must be established.)

{