3. Setup

3 - 110

3-6-2 Z phase automatic adjustment

Z-phase automatic adjustment is a function that automatically adjusts the relative position of the IPM

spindle motor pole and the PLG Z-phase pulse signal input into the spindle drive unit. The adjustment

data is saved in the drive unit, and is used to control the motor the next time the power is turned ON.

The motor cannot be started without completing this adjustment (alarm 16 will be detected), so always

carry out this adjustment when starting up the spindle system, when the spindle motor has been

replaced, when the PLG has been replaced or adjusted, or when the spindle drive unit has been

replaced.

<Adjustment methods>

[1] If SP205 is set to 1, change it to 0, and reboot the NC power. If it is already set to 0, go to step

[2].

[2] If the SP205 setting is 0, change it to 1.

[3] Input forward run start. The spindle motor will automatically rotate at the adjustment speed

(two stages for Z-phase pulse detection and pole position detection). (The control output

4/bitD is changed to 1 on the NC spindle monitor screen from startup until a restart occurs. In

the same manner, the control input 3/bit8 or bit9 status of 1 is established after the forward run

start input, and "D" is displayed for the drive unit until automatic adjustment is completed.)

[4] The adjustment results will be calculated and the operation will automatically stop approx. 90

seconds after forward run is started (may vary according to pole position). (When automatic

adjustment is completed, the drive unit display at the NC spindle monitor screen changes from

"D" to "C". Even though the motor is stopped while "D" is displayed, automatic adjustment is in

progress. Be sure to wait until "C" displays.)

[5] Turn forward run OFF. (The adjustment data will be saved.)

[6] Reboot the NC power.

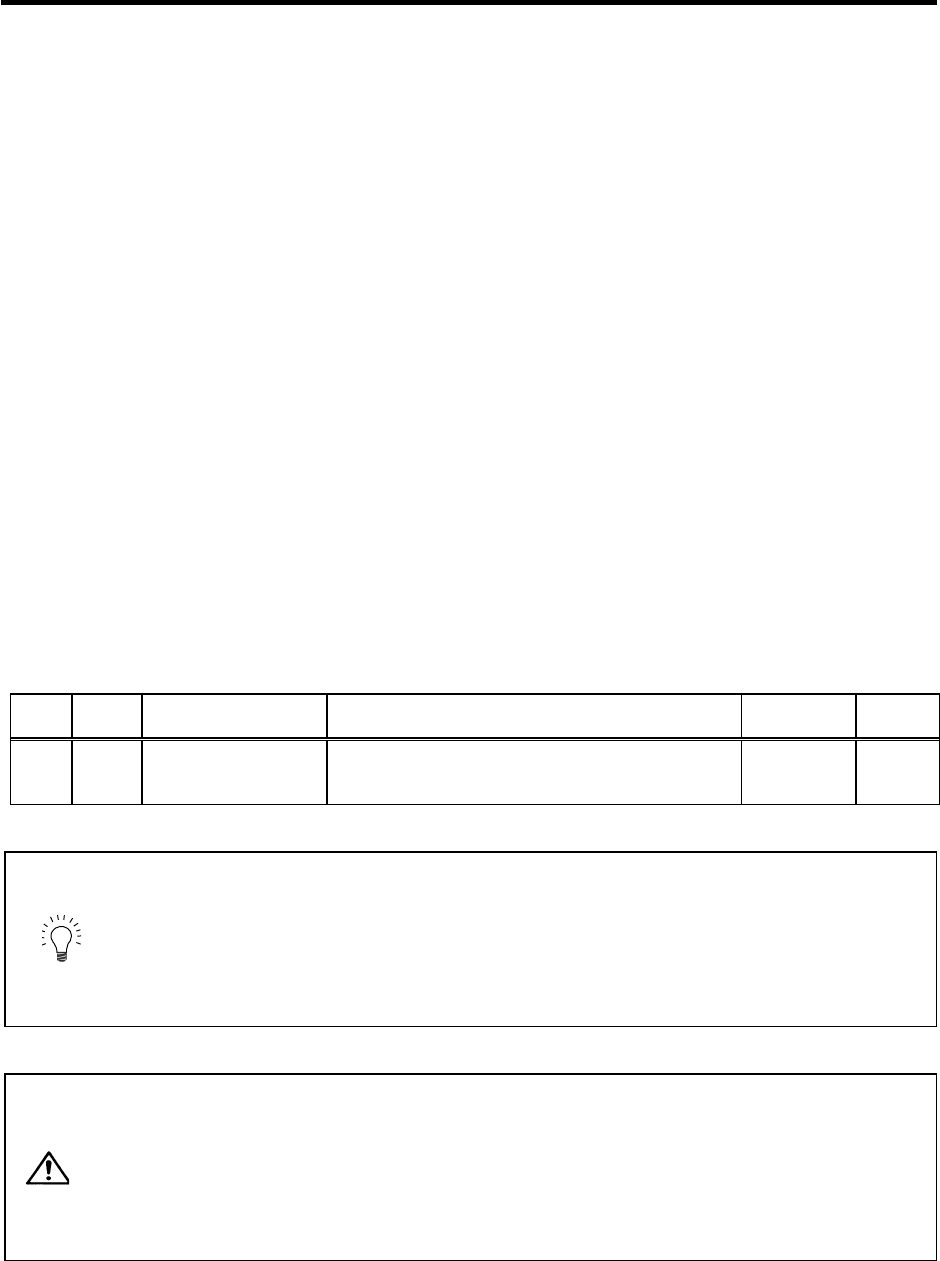

No. Abbr. Parameter name Details

Setting range

(Unit)

Standard

setting

SP205

ZCHS

PLG Z-phase automatic

adjustment

<For MDS-C1-SPM>

This validates the PLG Z-phase automatic adjustment

function

0 to 1

0 → 1

POINT

1. If the NC power is turned ON when SP205 is set to 1, the adjustment data

saved in the drive unit will be used for control.

2. To readjust, or to turn the start OFF during the automatic adjustment when

"D" is displayed for the drive unit (see step [4] above), specify another

SP205=0 setting to restart the NC, then perform the above procedure,

beginning from step [2].

3. If operation is started without completing the adjustment, alarm 16 will occur.

CAUTION

1. The motor will automatically rotate at the adjustment speed during Z-phase

automatic adjustment. Do not touch the rotating sections as this is

hazardous.

2. Complete PLG adjustment before starting this adjustment. (Built-in motor)

3. Keep the spindle load inertia and friction load as small as possible when

using this function. (The maximum inertia is approx. 5-fold the motor

inertia.)