6. Troubleshooting

6 - 18

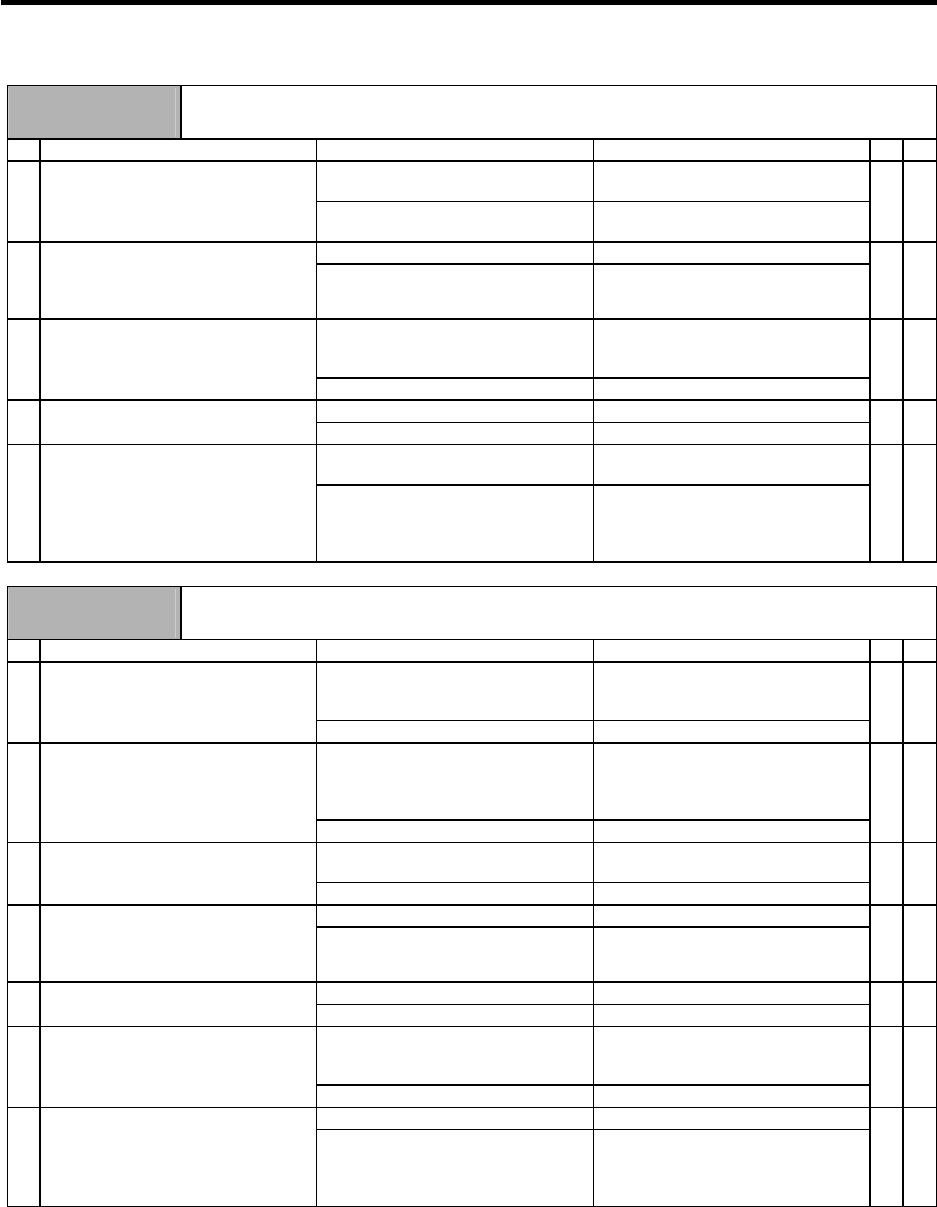

Alarm No.

31

Overspeed

A rotation speed exceeding the motor's tolerable rotation speed was detected.

Investigation details Investigation results Remedies SV SP

The rapid traverse rate is too fast. Set within the motor's maximum

rotation speed.

1 Check the rapid traverse rate (rapid)

and motor maximum rotation speed.

The speed is within the motor's

maximum rotation speed.

Investigate item 2.

{

The settings are incorrect. Correctly set. 2 Check the settings for the servo

parameters SV001 (PC1), SV002

(PC2), SV018 (PIT) and SV025

(MTYP).

Correctly set. Investigate item 5.

{

The setting is incorrect.

The alarm is detected at 115% of

SP017.

Correctly set. 3 Confirm the spindle parameter

SP017 (TSP) setting.

Correctly set. Investigate item 4.

{

There is a problem. Adjust the PLG output waveform. 4 Confirm the PLG output waveform.

Normal. Investigate item 5.

{

The waveform is overshooting. Increase the acceleration/

deceleration time constant.

5 Check whether the speed waveform

is overshooting.

The waveform is not overshooting. Check if there is any abnormality in

the unit's ambient environment.

(Ex.: Ambient temperature, noise,

grounding)

{ {

Alarm No.

32

Power module overcurrent

The power module's overcurrent protection function activated.

Investigation details Investigation results Remedies SV SP

The alarm occurs before READY ON.

(The drive unit is faulty.)

Check investigation item 2 and

following, and remove the cause of

the fault. Then replace the drive unit.

1 Check the repeatability.

The alarm occurs after READY ON. Investigate item 2.

{ {

The setting is incorrect.

Servo : SV025

Spindle : SP034, SP040, SP257 to

SP384

Correctly set.

2 Check the parameter setting.

• Motor type

The setting is correct. Investigate item 3.

{ {

The setting is large compared to the

standard value.

Set the standard value. 3 Check the parameter settings.

• Current loop gain

• Speed loop gain

The standard value is set. Investigate item 4.

{ {

The power cable is short-circuited. Replace the motor's power cable. 4 Disconnect the UVW phase wiring

from the terminal block, and the

cannon plug from the motor. Check

the insulation with a tester.

There is no problem. Investigate item 5.

{ {

The power cable is short-circuited. Replace the motor's power cable. 5 Check the insulation between the

motor power cable and FG.

There is no problem. Investigate item 6.

{ {

The motor is short-circuited. Replace the motor.

(With the absolute position system,

the zero point must be established.)

6 Connect the cannon plug, and check

the insulation between the power

cable and FG.

There is no problem. Investigate item 7.

{ {

No abnormality is found in particular. Replace the drive unit. 7 Check for any abnormalities in the

motor's ambient environment.

(Ex.: Ambient temperature, cutting

water)

An abnormality was found in the

ambient environment.

Replace the motor and improve the

motor installation environment.

(With the absolute position system,

the zero point must be established.)

{ {