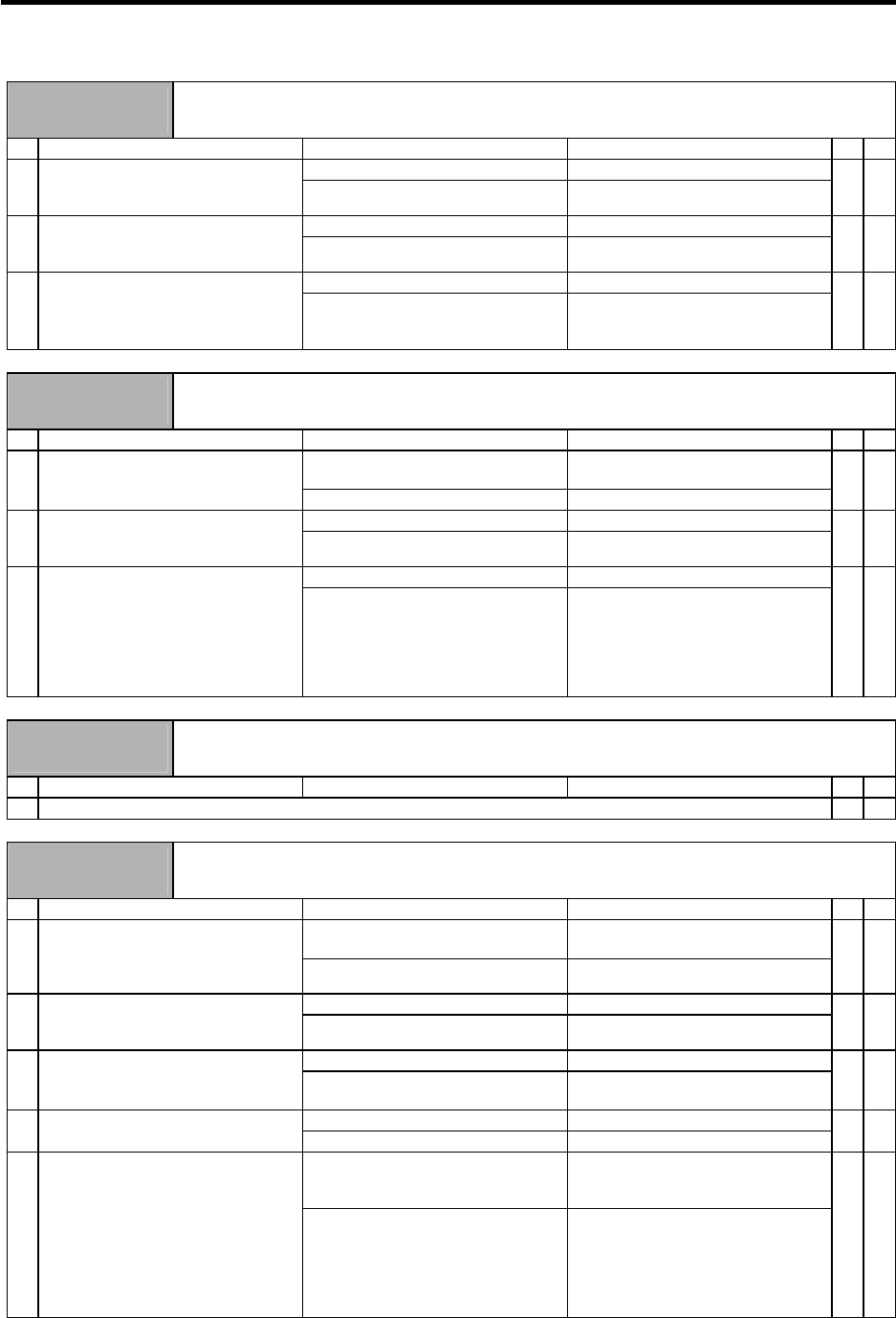

6. Troubleshooting

6 - 23

Alarm No.

3F

Speed excessive deflection 2

During constant speed operation, the difference between the speed command and speed feedback

exceeded the set amount and set time.

Investigation details Investigation results Remedies SV SP

The cutting load is large. Lower the cutting load. 1 Check the load value with the spindle

monitor, and investigate the

machine's load state.

The cutting load is not large. Investigate item 2.

{

Locked with a mechanical lock. Remove the cause of the lock. 2 Check whether the spindle rotary

section is locked with a mechanical

lock (C-axis clamp, etc.).

Not locked with a mechanical lock. Investigate item 3.

{

Improved. Replace the drive unit. 3 Try replacing the drive unit.

Not improved. Investigate the motor.

(Check the motor type and

parameters.)

{

Alarm No.

40

Detector changeover unit, changeover error

During 1-drive unit 2-motor control, an error was detected in the motor changeover signal received form

the detector changeover unit.

Investigation details Investigation results Remedies SV SP

The connector is disconnected (or

loose).

Correctly install. 1 Wiggle the FR-TK unit connector by

hand to check whether it is

disconnected.

The connector is not disconnected. Investigate item 2.

{

The cable is broken. Replace the cable. 2 Check whether the cable connected

between the spindle drive unit and

FR-TK unit is broken.

The cable is not broken. Investigate item 3.

{

No abnormality is found in particular. Replace the drive unit. 3 Check if there is any abnormality in

the unit's ambient environment.

(Ex. Ambient temperature, noise,

grounding)

An abnormality was found in the

ambient environment.

Take remedies according to the

causes of the abnormality.

Ex. High temperature:

Check the cooling fan.

Incomplete grounding:

Additionally ground.

{

Alarm No.

41

Detector changeover unit, communication error

During 1-drive unit 2-motor control, an error was detected in the communication with the detector

changeover unit.

Investigation details Investigation results Remedies SV SP

1 Check the alarm No. "40" items.

{

Alarm No.

42

Feedback error 1

With the servo, pulse-type position detector feedback signal error was detected. With the spindle, a

PLG feedback signal error was detected.

Investigation details Investigation results Remedies SV SP

The connector is disconnected (or

loose).

Correctly install. 1 Check whether the drive unit

connectors (servo: CN3, spindle:

CN6) or detector connectors are

disconnected.

The connector is not disconnected. Investigate item 2.

{ {

There is a connection fault. Replace the detector cable. 2 Turn the power OFF, and check the

detector cable connection with a

tester.

The connection is normal. Investigate item 3.

{ {

The alarm is on the drive unit side. Replace the drive unit. 3 Connect to another normal axis drive

unit, and check whether the fault is

on the drive unit side or detector side.

The alarm is on the detector side. Servo : Investigate item 5.

Spindle : Investigate item 4.

{ {

There is a problem. Adjust the PLG output waveform. 4 Check the PLG output waveform.

Normal Investigate item 5.

{

No abnormality is found in particular. Replace the detector.

(With the absolute position system,

the zero point must be established.)

5 Check if there is any abnormality in

the detector's ambient environment.

(Ex. Ambient temperature, noise,

grounding)

An abnormality was found in the

ambient environment.

Take remedies according to the

causes of the abnormality.

Ex. High temperature:

Check the cooling fan.

Incomplete grounding:

Additionally ground.

{ {