4. Servo Adjustment

4 - 25

(3) Adjusting the lost motion compensation timing

If the speed loop gain has been lowered from the standard setting value because the machine

rigidity is low or because machine resonance occurs easily, or when cutting at high speeds, the

quadrant protrusion may appear later than the quadrant changeover point on the servo control. In

this case, suppress the quadrant protrusion by setting the lost motion compensation timing

(SV039: LMCD) to delay the LMC compensation.

<Adjustment method>

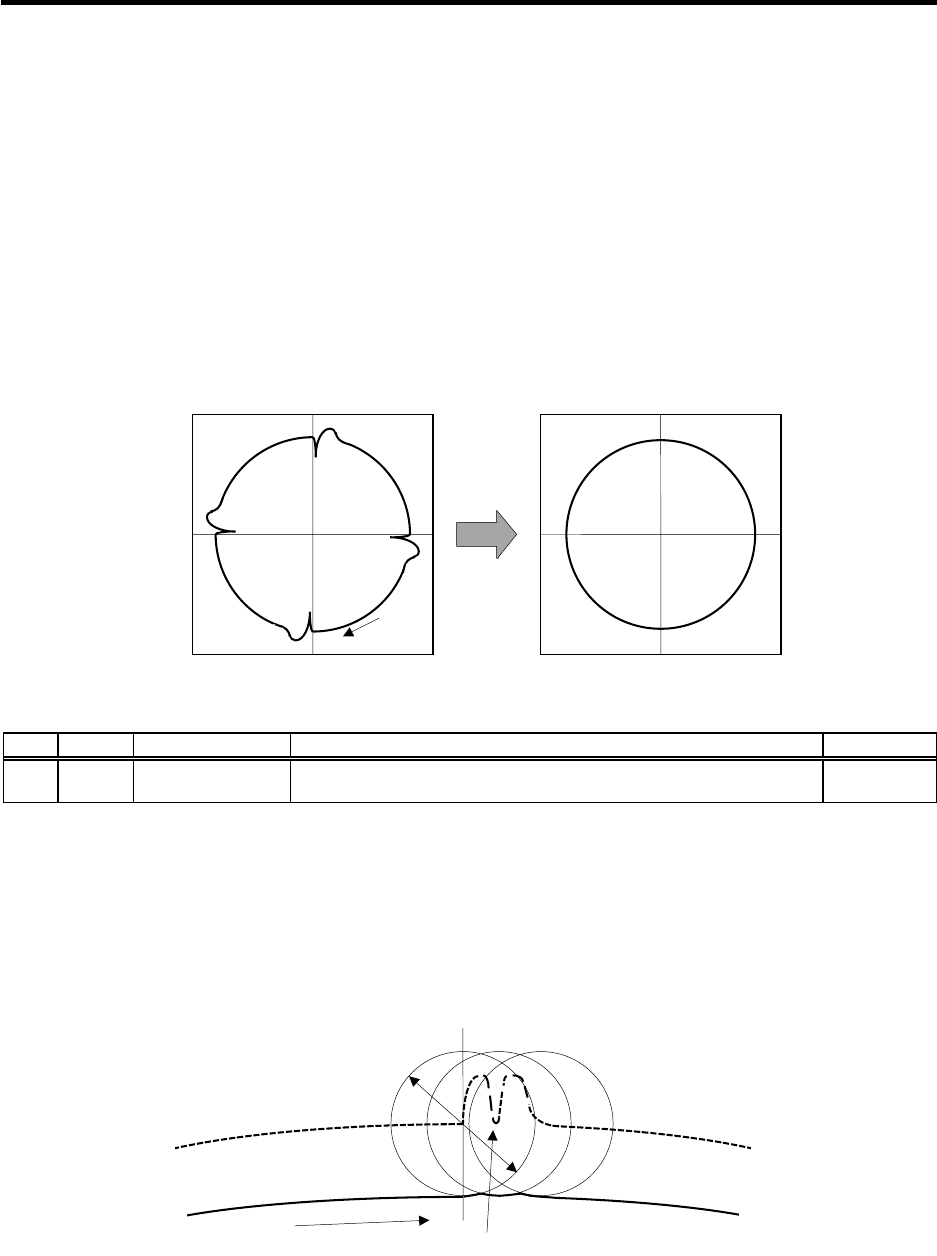

If a delay occurs in the quadrant protrusion in the circle or arc cutting as shown below in respect to

the cutting direction when CNC sampling measurement (DBB measurement) or actual cutting is

carried out, and the compensation appears before the protrusion position, set the lost motion

compensation timing (SV039: LMCD).

While measuring the arc path, increase LMCD by 10 ms at a time, to find the timing that the

protrusion and compensation position match.

Before timing delay compensation After timing delay compensation

No. Abbrev. Parameter name Explanation Setting range

SV039 LMCD Lost motion

compensation timing

Set this when the lost motion compensation timing does not match. Adjust

while increasing the value by 10 at a time.

0 to 2000

(ms)

When the LMCD is gradually raised, a two-peaked contour may occur at the motor FB position

DBB measurement. However, due to the influence of the cutter diameter in cutting such as end

milling, the actual cutting surface becomes smooth.

Because satisfactory cutting can be achieved even if this two-peaked contour occurs, consider the

point where the protrusion becomes the smallest and finest possible without over compensating

(bite-in) as the optimum setting.

Cutter center path

A

ctual cutting surface

Cutting direction

Quadrant changeover point

Point of LMC compensation execution

Cutter diameter

A

fter

compensation

Cutting

direction