4. Servo Adjustment

4 - 46

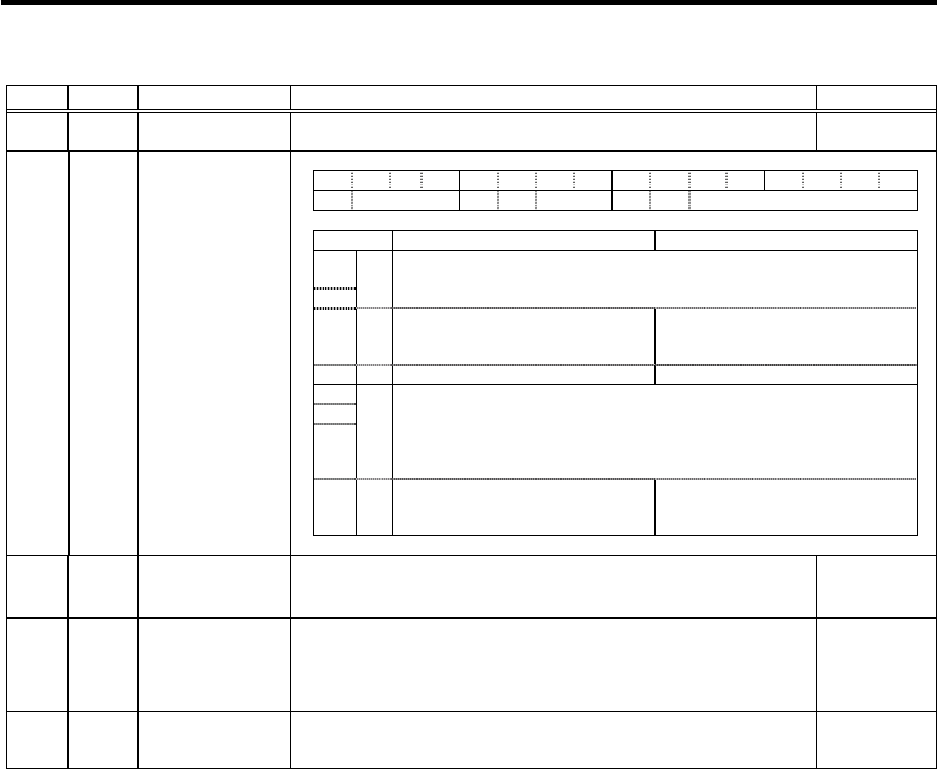

No. Abbrev. Parameter name Explanation Setting range

SV032 TOF Torque offset

Set the unbalance torque of vertical axis and inclined axis. -100 to 100

(Stall current %)

SV035 SSF4 Servo function

selection 4 F E D C B A 9 8 7 6 5 4 3 2 1 0

clt clG1 cl2n clet cltq iup tdt

bit Meaning when "0" is set Meaning when "1" is set

8

Set the retracting torque for collision detection in respect to the maximum

torque of the motor.

9

cltq

00 : 100% 01 : 90% 10 : 80% (Standard) 11 : 70%

A clet

Setting for normal use The disturbance torque peak of the

latest two seconds is displayed in

MPOS of the servo monitor screen.

B cl2n Collision detection method 2 valid Collision detection method 2 invalid

C

D

E

clG1

Collision detection method 1

Set the collision detection level during cutting feed (G1).

The G1 collision detection level=SV060

× clG1.

When clG1=0, the collision detection method 1 during cutting feed won’t

function.

F clt

Setting for normal use The guide value of the SV059

setting value is displayed in MPOS

of the servo monitor screen.

SV045 TRUB

(Low

order)

Frictional torque

When you use the collision detection function, set the frictional torque. 0 to 100

(Stall current %)

SV059 TCNV Collision detection

torque estimating

gain

Set the torque estimating gain when using the collision detection function.

After setting as SV035/bitF(clt)=1 and performing

acceleration/deceleration, set the value displayed in MPOS of the NC

servo monitor screen.

Set to "0" when not using the collision detection function.

-32768 to

32767

SV060 TLMT Collision detection

level

When using the collision detection function, set the collision detection

level during the G0 feeding.

If "0" is set, none of the collision detection function will work.

0 to 999

(Stall current %)