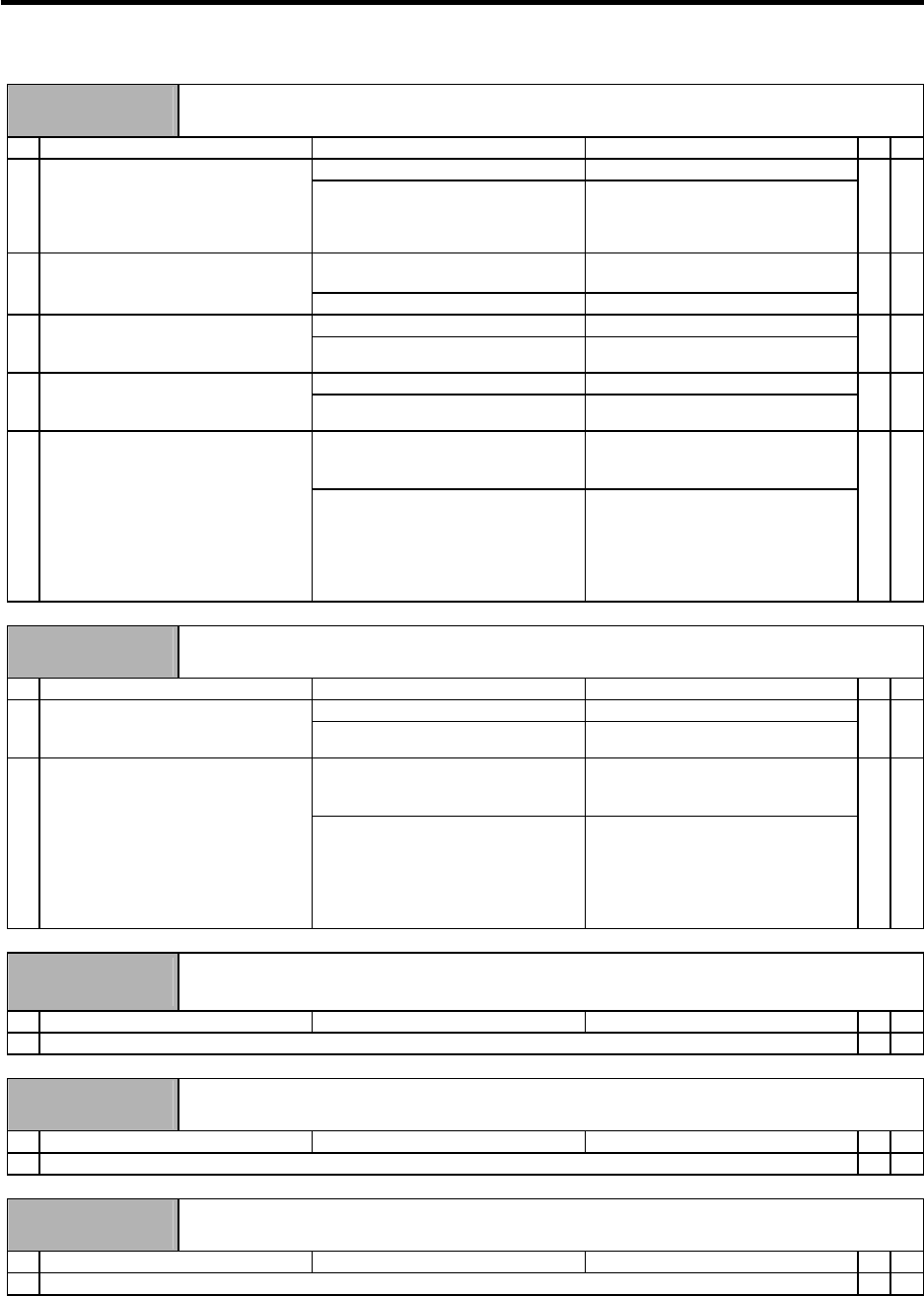

6. Troubleshooting

6 - 13

Alarm No.

1A

Machine side detector, initial communication error

Initial communication with the linear scale or ball screw end detector was not possible.

Investigation details Investigation results Remedies SV SP

The value is not set correctly. Correctly set SV025. 1 Check the servo parameter

(SV025.pen) setting value.

Are the serial communication

parameters set for the pulse-type

detector?

The value is set correctly. Investigate item 2.

{

The connector is disconnected (or

loose).

Correctly install. 2 Check whether the drive unit

connectors (CN3) or detector

connectors are disconnected.

The connector is not disconnected. Investigate item 3.

{

There is a connection fault. Replace the detector cable. 3 Turn the power OFF, and check the

detector cable connection with a

tester.

The connection is normal. Investigate item 4.

{

The alarm is on the drive unit side. Replace the drive unit. 4 Connect to another normal axis drive

unit, and check whether the fault is

on the drive unit side or detector side.

The alarm is on the detector side. Investigate item 5.

{

No abnormality is found in particular. Replace the detector.

(With the absolute position system,

the zero point must be established.)

5 Check if there is any abnormality in

the detector's ambient environment.

(Ex. Ambient temperature, noise,

grounding)

An abnormality was found in the

ambient environment.

Take remedies according to the

causes of the abnormality.

Ex. High temperature:

Check the cooling fan.

Incomplete grounding:

Additionally ground.

{

Alarm No.

1B

Machine side detector, CPU error 1

A CPU initial error was detected with the linear scale or ball screw end detector.

Investigation details Investigation results Remedies SV SP

The alarm is on the drive unit side. Replace the drive unit. 1 Connect to another normal axis drive

unit, and check whether the fault is

on the drive unit side or scale side.

The alarm is on the detector side. Investigate item 2.

{

No abnormality is found in particular. Replace the detector.

(With the absolute position system,

the zero point must be established.)

2 Check if there is any abnormality in

the detector's ambient environment.

(Ex. Ambient temperature, noise,

grounding)

An abnormality was found in the

ambient environment.

Take remedies according to the

causes of the abnormality.

Ex. High temperature:

Check the cooling fan.

Incomplete grounding:

Additionally ground.

{

Alarm No.

1C

Machine side detector, EEPROM/LED abnormality

An error was detected in the data stored in the memory by the linear scale. Or, LED deterioration was

detected with the linear scale.

Investigation details Investigation results Remedies SV SP

1 Check the alarm No. "1B" items.

{

Alarm No.

1D

Machine side detector, data error

A data error was detected with the linear scale or ball screw end detector.

Investigation details Investigation results Remedies SV SP

1 Check the alarm No. "1B" items.

{

Alarm No.

1E

Machine side detector, memory error

An internal memory error was detected with the linear scale.

Investigation details Investigation results Remedies SV SP

1 Check the alarm No. "1B" items.

{