4. Servo Adjustment

4 - 24

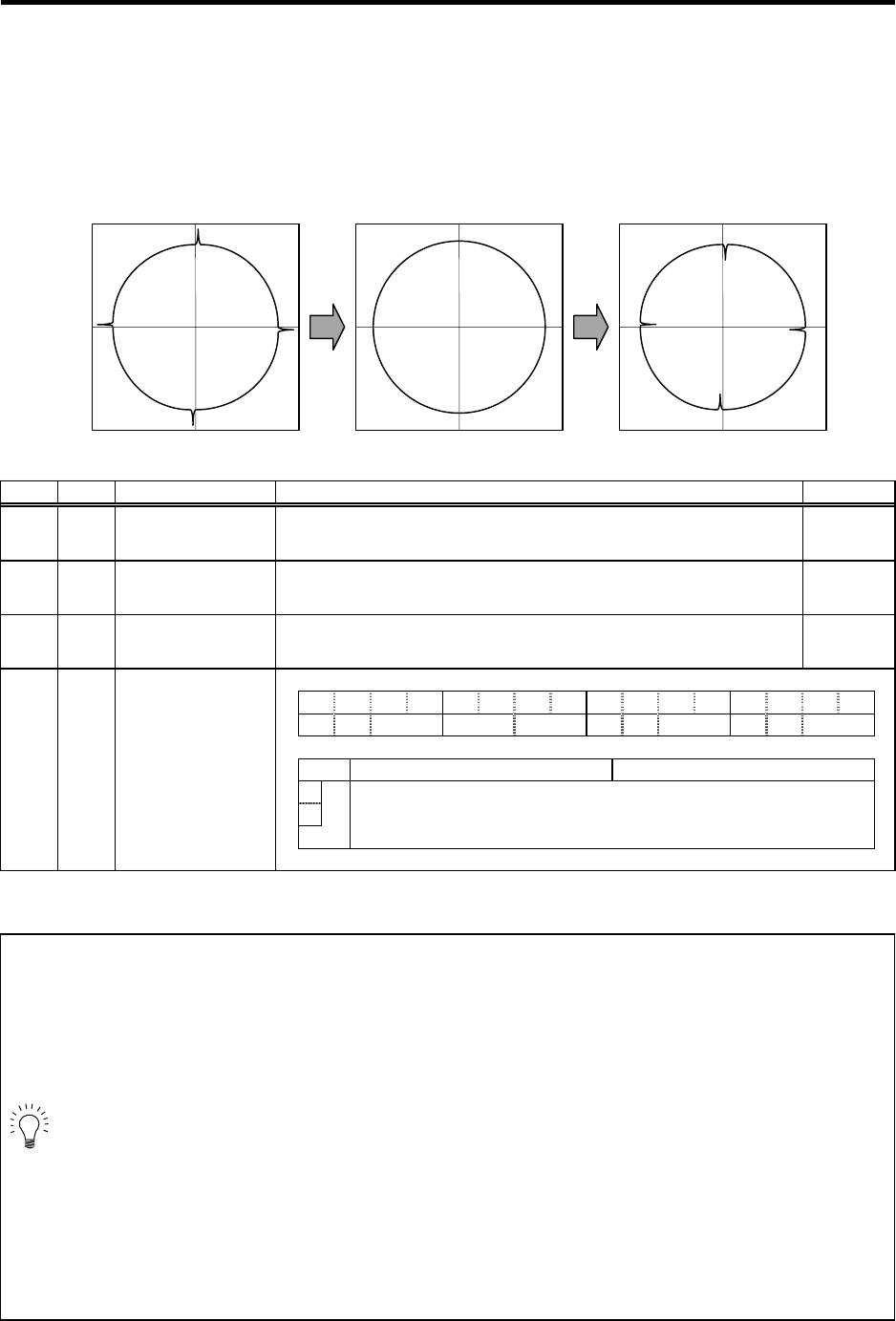

<Adjustment method>

Perform the final adjustment, carrying out the NC sampling measurement (DBB measurement) or

actual cutting. If the compensation amount is insufficient, increase LMC1 or LMC2 by 5% at a time.

Note that if the setting is too high, biting may occur.

No. Abbrev. Parameter name Explanation Setting range

SV016 LMC1 Lost motion

compensation 1

Set the compensation amount based on the stall (rated) current of the motor.

The standard setting is double of the friction torque. Setting to "0" means the

compensation amount is zero.

-1 to 200

(Stall [rated]

current %)

SV041 LMC2 Lost motion

compensation 2

Set this with SV016 (LMC1) only when you wish to set the lost motion

compensation amount to be different depending on the command directions.

Set to "0" as a standard.

-1 to 200

(Stall [rated]

current %)

SV032 TOF Torque offset This setting is specified when using lost motion compensation.

Set the unbalance torque of vertical axis and inclined axis.

-100 to 100

(Stall [rated]

current %)

F E D C B A 9 8 7 6 5 4 3 2 1 0

aflt zrn2 afse ovs lmc omr zrn3 vfct upc vcnt

bit Meaning when "0" is set Meaning when "1" is set

8 Set the compensation amount with SV016 (LMC1) and SV041 (LMC2).

9

lmc

00: Lost motion compensation stop 10: Lost motion compensation type 2

01: Lost motion compensation type 1 11: Setting prohibited

SV027 SSF1

Servo function

selection 1

POINT

1. Set SV082/bit1=0 when using LMC compensation type 2.

2. When either parameter SV016: LMC1 or SV041: LMC2 is set to 0, the same

amount of compensation is carried out in both the positive and negative direction

with the setting value of the other parameter (the parameter not set to 0).

3. When the protrusion amount varies according to direction, use LMC2 to adjust it.

For compensation in one direction only, set "-1" at the parameter (LMC1 or LMC2)

for the direction in which compensation is prohibited.

4. Even if a TOF is set, the motor's torque output characteristics and the load current

displayed at the NC servo monitor will remain unchanged. Only the LMC

compensation is affected.

5. The value set based on the friction torque is the standard value for LMC

compensation. The optimum compensation value changes with the cutting

conditions (cutting speed, cutting radius, blade type, workpiece material, etc.). Be

sure to ultimately make test cuts matching the target cutting and determine the

compensation amount.

Optimum Compensation 0 Too high