5. Spindle Adjustment

5 - 20

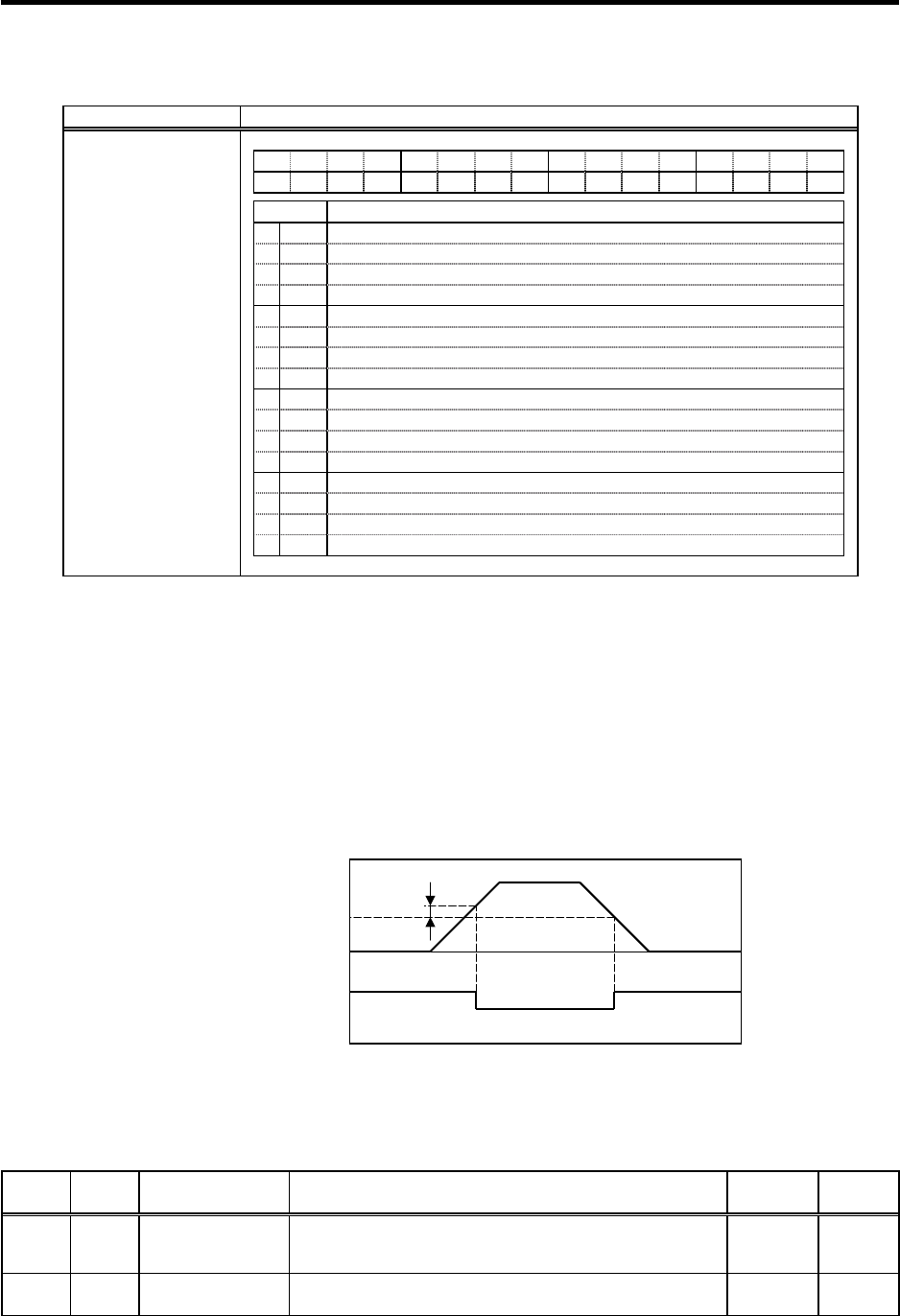

(4) Spindle control output 4

Name Details

F E D C B A 9 8 7 6 5 4 3 2 1 0

ORF2 TLUA

ATA

OSPA

PYVA

SD2 MTC

WRCF

MKC

SYSA

ORCF

ZS US SD1 CD

bit Details

0

CD

Current detection

1

SD1

Speed detection 1

2

US

Up-to-speed

3

ZS

Zero speed

4

ORCF

Orientation complete

5

SYSA

Synchronous speed match

6

MKC

Changing coil

7

WRCF

Index positioning completed

8

MTC

In changeover (for 1-drive unit 2-motor changeover)

9

SD2

Speed detection 2

A

B

PYVA

In minimum weak excitation value changeover

C

OSPA

Orientation speed changeover state

D

ATA

In automatic adjustment (only for MDS-C1-SPM)

E

TLUA

Spindle holding force increased

F

ORF2

2nd orientation completed

Spindle control output 4

bit0. Current detection (CD)

This signal turns ON when the start signal (forward run, reverse run, orientation) is ON, and the

current flowing to the motor is approx. 110% or more of the rating. (The motor output (current)

guarantee value is 120% of the rating.)

bit1. Speed detection 1 (SD1)

This signal turns ON when the motor speed drops below the value set with parameter SP020

(SDTS). The ON to OFF hysteresis width is set with parameter SP047 (SDTR). This signal turns

ON when the motor's speed is less than the set speed regardless of the input signal state.

Speed detection 1 (SD1) sequence

Related spindle parameters

No. Abbr. Parameter name Details

Setting

range

Standard

SP020 SDTS* Speed detection set

value

Set the motor speed for which speed detection output is

performed.

Usually, the setting value is 10% of SP017 (TSP).

0 to 32767

(r/min)

600

SP047 SDTR* Speed detection

reset value

Set the reset hysteresis width for a speed detection set value

defined in SP020 (SDTS).

0 to 1000

(r/min)

30

SP047

Motor speed

Speed detection 1 (SD1)

ON

OFF

SP020

0