3. Setup

3 - 109

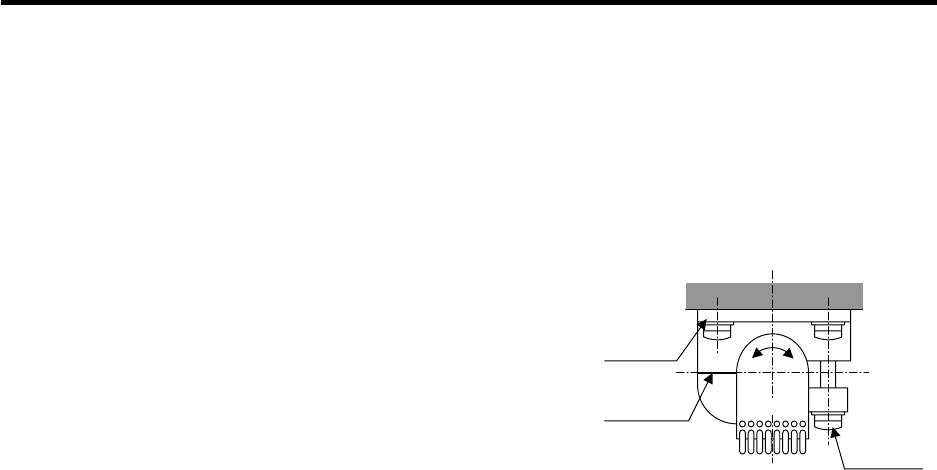

(8) Adjusting the Z phase and A phase difference

[1] Stop the motor, and make sure that the detection gears are not rotating. The sensor could be

damaged if adjustments are carried out while the gears are rotating.

[2] Using a clearance gauge, adjust so that the gap between the sensor direction surface and the

detection gears’ circumference is 0.15±0.01mm, and loosen the sensor fixing screw.

[3] The phase difference of the Z phase to the A phase can be adjusted by rotating the sensor as

shown on the right. At this time, rotate the sensor a little bit while using the marking lines on

the sensor and installation seat as a guide.

[4] Tighten the sensor fixing screw so that the sensor

does not move, and confirm that the gap between the

sensor detection surface and detection gears'

circumference is 0.15 ± 0.01mm. Then, rotate the

gears and confirm the phase difference as explained

above.

[5] When the phase difference is within the tolerable

range, apply a locking agent on the sensor fixing

screw, and then fix the sensor. Check the gap again

after fixing the sensor.

Always carry out the initial automatic adjustment when starting the spindle system up for the first

time or when the spindle drive unit has been replaced.

[1] MDS-C1-SPM : "3-6-2 Z-phase automatic adjustment" + "3-6-3 Motor end PLG

automatic adjustment"

[2] MDS-C1-SP/SPH : "3-6-3 Motor end PLG automatic adjustment"

[3] MDS-C1-SPX/SPHX : "3-6-4 Spindle end PLG automatic adjustment"

Marking

line

Rotate

Sensor

fixing

screw

Sensor

installation

seat

Adjusting the Z phase difference