4. Servo Adjustment

4 - 9

4-3 Characteristics improvement

4-3-1 Optimal adjustment of cycle time

The following items must be adjusted to adjust the cycle time. Refer to the Instruction Manuals provided

with each CNC for the acceleration/deceleration pattern.

[1] Rapid traverse rate (rapid) : This will affect the maximum speed during positioning.

[2] Clamp speed (clamp) : This will affect the maximum speed during cutting.

[3] Acceleration/deceleration time : Set the time to reach the feedrate.

constant (G0t∗, G1t∗)

[4] In-position width (SV024) : This will affect each block's movement command end time.

[5] Position loop gain (SV003) : This will affect each block's movement command settling time.

(1) Adjusting the rapid traverse

To adjust the rapid traverse, the CNC axis specification parameter rapid traverse rate (rapid) and

acceleration/deceleration time constant (G0t∗) are adjusted. The rapid traverse rate is set so that

the motor speed matches the machine specifications in the range below the maximum speed in the

motor specifications. For the acceleration/deceleration time constants, carry out rapid traverse

reciprocation operation, and set so that the maximum current command value at acceleration/

deceleration is within the range shown below. The output torque is limited at areas near the

maximum speed, so monitor the current FB waveform during acceleration/deceleration and adjust

so that the torque is within the specified range.

If the drive unit's input voltage is less than the rated voltage, the torque will easily become

insufficient, and excessive errors will occur easily during acceleration/deceleration.

(2) Adjusting the cutting feed

To adjust the cutting rate, the NC axis specification parameter clamp speed (clamp) and

acceleration/deceleration time constant (G1t∗) are adjusted. The in-position width at this time must

be set to the same value as actual cutting.

• Determining the clamp rate and adjusting the acceleration/deceleration time constant

(Features) The maximum cutting rate (clamp speed) can be determined freely.

(Adjustment) Carry out cutting feed reciprocation operation with no dwell at the maximum

cutting rate and adjust the acceleration/deceleration time constant so that the

maximum current command value during acceleration/deceleration is within the

range shown below.

• Setting the step acceleration/deceleration and adjusting the clamp speed

(Features) The acceleration/deceleration time constant is determined with the position loop

in the servo, so the acceleration/deceleration F∆T can be reduced.

(Adjustment) Set 1 (step) for the acceleration/deceleration time constant and carry out cutting

feed reciprocation operation with no dwell. Adjust the cutting feed rate so that the

maximum current command value during acceleration/deceleration is within the

range shown below, and then set the value in the clamp speed.

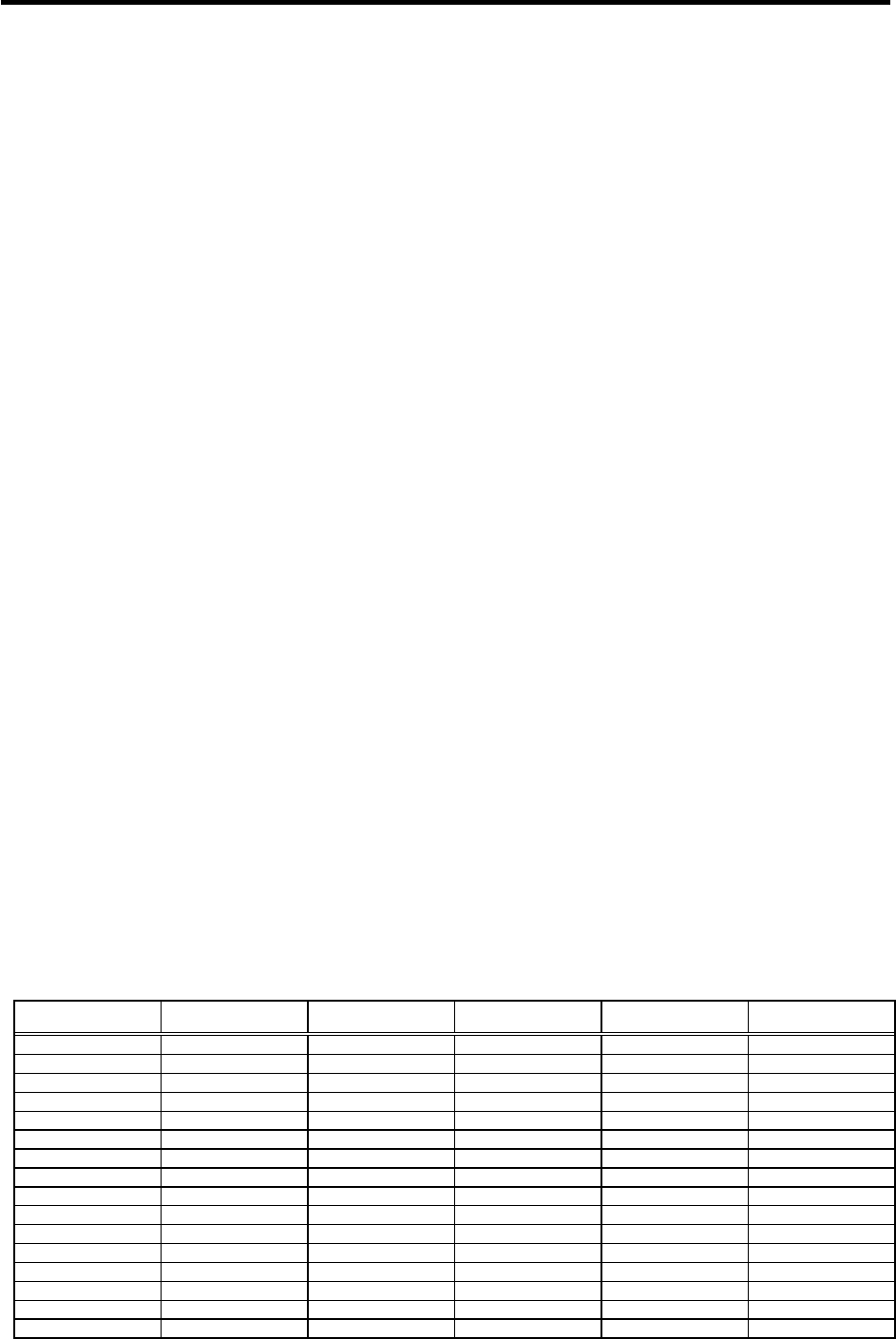

Maximum current command value when adjusting acceleration/deceleration time constant

Motor model

Max. current

command value

Motor model

Max. current

command value

Motor model

Max. current

command value

HC52 Within 388% HA053N Within 240% HA40N Within 400%

HC102 Within 340% HA13N Within 240% HA80N Within 365%

HC152 Within 380% HA23N Within 230% HA100N Within 260%

HC202 Within 275% HA33N Within 230% HA200N Within 225%

HC352 Within 251% HA300N Within 200%

HC452 Within 189% HA-LF11K2 Within 215% HA700N Within 205%

HC702 Within 221% HA-LF15K2 Within 240% HA900N Within 220%

HC902 Within 228%

HC452* Within 242% HA43N Within 295%

HC53 Within 264% HC702* Within 248% HA83N Within 275%

HC103 Within 257% HC902* Within 228% HA103N Within 245%

HC153 Within 266% HA203N Within 210%

HC203 Within 257% HC353* Within 242% HA303N Within 180%

HC353 Within 230% HC453* Within 248% HA703N Within 180%

HC453 Within 177% HC703* Within 228%

HC703 Within 189%

(Note) The motor indicated with an asterisk indicates the combination with the S-type drive unit.