3. Setup

3 - 40

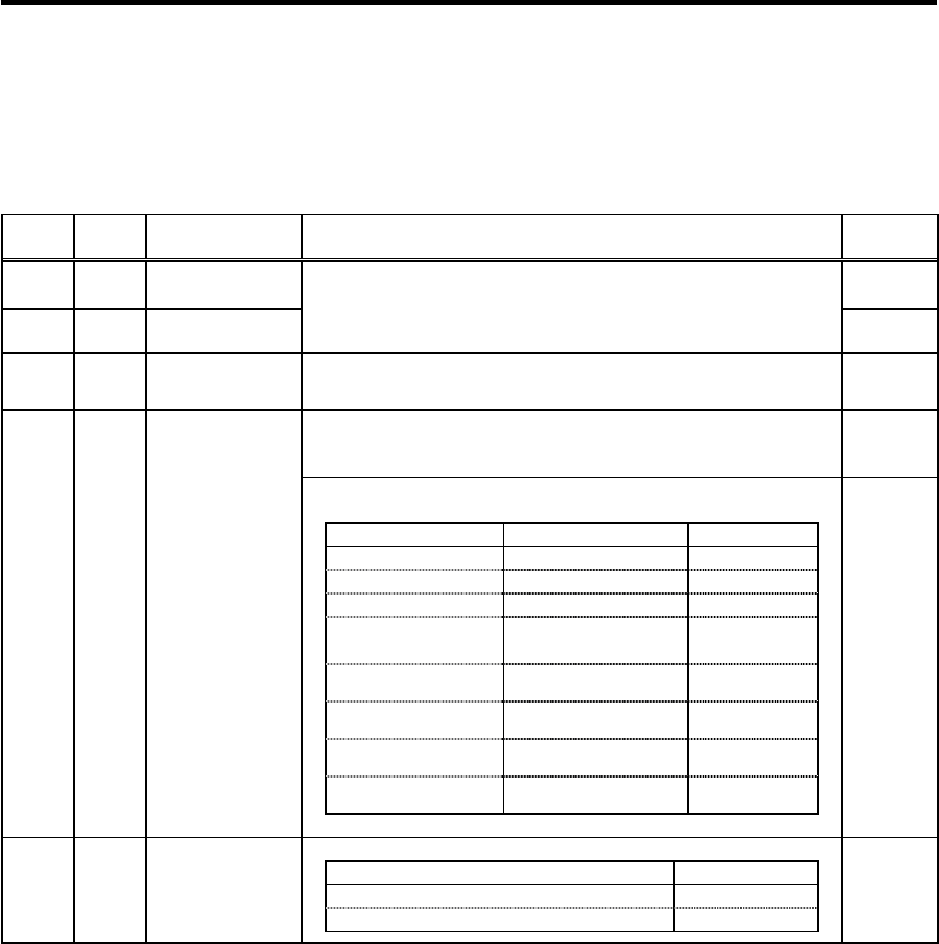

(2) Electronic gear related parameters

The setting range of the following parameters, which configure the electronic gears, may be limited

according to the combination. Refer to section "3-4 Restrictions on servo control" for details.

Standard specifications

No. Abbrev. Parameter name Explanation

Setting

range (Unit)

SV001 PC1*

Motor side gear

ratio

1 to 32767

SV002 PC2*

Machine side gear

ratio

Set the motor side and machine side gear ratio.

For the rotary axis, set the total deceleration (acceleration) ratio.

Even if the gear ratio is within the setting range, the electronic gears may

overflow and cause an alarm.

1 to 32767

SV018 PIT*

Ball screw pitch

Set the ball screw pitch. Set to “360” for the rotary axis.

1 to 32767

(mm/rev)

In the case of the semi-closed loop control

Set the same value as SV020 (RNG2). (Refer to the explanation of

SV020.)

1 to 9999

(kp/rev)

In the case of the full-closed loop control

Set the number of pulses per ball screw pitch.

Detector model name Resolution SV019 setting

OHE25K-ET, OHA25K-ET 100,000 (p/rev) 100

OSE104-ET,OSA104-ET 100,000 (p/rev) 100

OSE105-ET,OSA105-ET 1,000,000 (p/rev) 1000

Relative position detection

scale

Refer to detector

specification manual

PIT/Resolution

(

µm)

AT41 (Mitsutoyo) 1 (µm/p)

The same as

SV018 (PIT)

AT342 (Mitsutoyo) 0.5 (µm/p)

Twice as big as

SV018 (PIT)

FME type, FLE type

(Futaba)

Refer to detector

specification manual

PIT/Resolution

(

µm)

MP type (Mitsubishi Heavy

Industries)

Refer to detector

specification manual

PIT/Resolution

(

µm)

SV019 RNG1*

Position detector

resolution

1 to 9999

(kp/pit)

Set the number of pulses per one revolution of the motor end detector.

Detector model name SV020 setting

OSE104, OSA104 100

OSE105, OSA105 1000

SV020 RNG2*

Speed detector

resolution

1 to 9999

(kp/rev)

Parameters with an asterisk * in the abbreviation, such as PC1*, are validated with the NC power turned ON again.