6. Troubleshooting

6 - 44

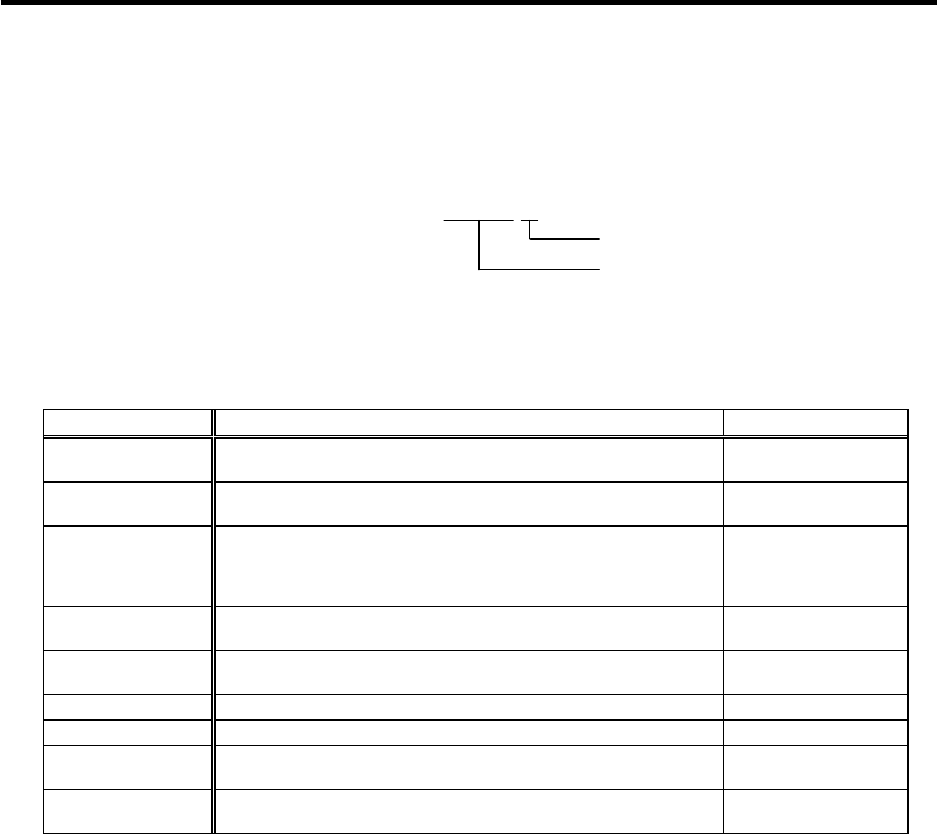

6-3-4 Parameter numbers during initial parameter error

If an initial parameter error (alarm 37) occurs, the alarm and the number of the parameter that may

have been set exceeding the setting range will appear on the CNC Diagnosis screen. (For M60S, E60

Series NC.)

S02 Initial parameter error {{{{

Axis name

Error parameter

If an error number larger than the servo parameter number is displayed for the servo drive unit

(MDS-C1-V1/V2), the alarm is occurring for several related parameters. Refer to the following table,

and correctly set the parameters.

Error parameter No. Details Related parameters

2269 The CNC setting maximum rapid traverse rate value is incorrect.

The CNC system software may be illegal. Turn the power ON again.

NC setting

rapid

2271 The CNC setting maximum cutting speed setting value is incorrect.

The CNC system software may be illegal. Turn the power ON again.

NC setting

clamp

2301 The following settings are overflowing.

Electronic gears

Position loop gain

Speed feedback

SV001, SV002 SV003,

SV018

SV019, SV020

SV049

2302 The absolute position parameter is valid when OSE104 and OSE105

are connected.

SV017, SV025

2303 The servo option is not available.

The closed loop or dual feedback control function is set.

SV025, SV017

2304 The servo option is not available. The SHG control function is set. SV057, SV058

2305 The servo option is not available. The adaptive filter function is set. SV027

2306 The servo option is not available. The MP scale absolute position

function is set.

SV017

2308 The valid/invalid setting of the 4th or 5th notch filter is changed from

the initial setting.

SV087, SV088