1. Installation

1 - 5

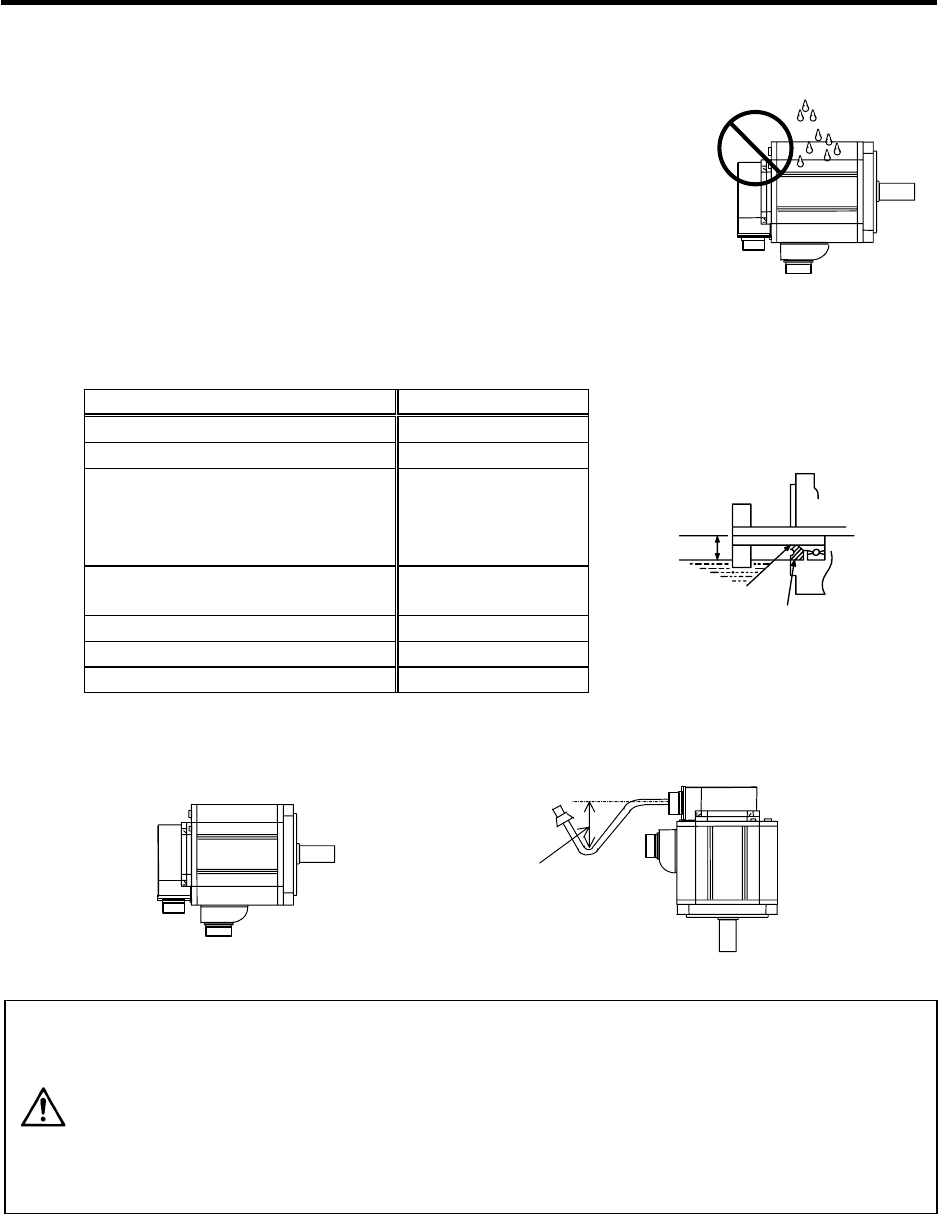

1-1-6 Oil/water standards

[1] The motor protective format uses the IP type, which complies with IEC

Standard. However, these Standards are short-term performance

specifications. They do not guarantee continuous environmental

protection characteristics. Measures such as covers, etc., must be

taken if there is any possibility that oil or water will fall on the motor,

and the motor will be constantly wet and permeated by water. Note

that the motor’s IP-type is not indicated as corrosion-resistant.

[2] When a gear box is installed on the servomotor, make sure that the oil

level height from the center of the shaft is higher than the values given below. Open a breathing

hole on the gear box so that the inner pressure does not rise.

Servomotor Oil level (mm)

HA053N, HA13N 8

HA23N, HA33N 10

HC52, HC102, HC152

HC53, HC103, HC153

HC103R, HC153R, HC203R

HC353R, HC503R

20

HC202, HC352, HC452, HC702

HC203, HC353, HC453, HC703

25

HC902 30

HA-LF11K2-S8 34

HA-LF15K2-S8 48

Oil level

Lip

V-ring

Servomoto

r

Gea

r

[3] When installing the servomotor horizontally, set the power cable and detector cable to face

downward. When installing vertically or on an inclination, provide a cable trap.

Cable trap

CAUTION

1. The servomotors, including those having IP65 specifications, do not have a

completely waterproof (oil-proof) structure. Do not allow oil or water to

constantly contact the motor, enter the motor, or accumulate on the motor. Oil

can also enter the motor through cutting chip accumulation, so be careful of

this also.

2. When the motor is installed facing upwards, take measures on the machine

side so that gear oil, etc., does not flow onto the motor shaft.

3. Do not remove the detector from the motor. (The detector installation screw is

treated for sealing.)

Oil or water

Servomotor