5. Spindle Adjustment

5 - 49

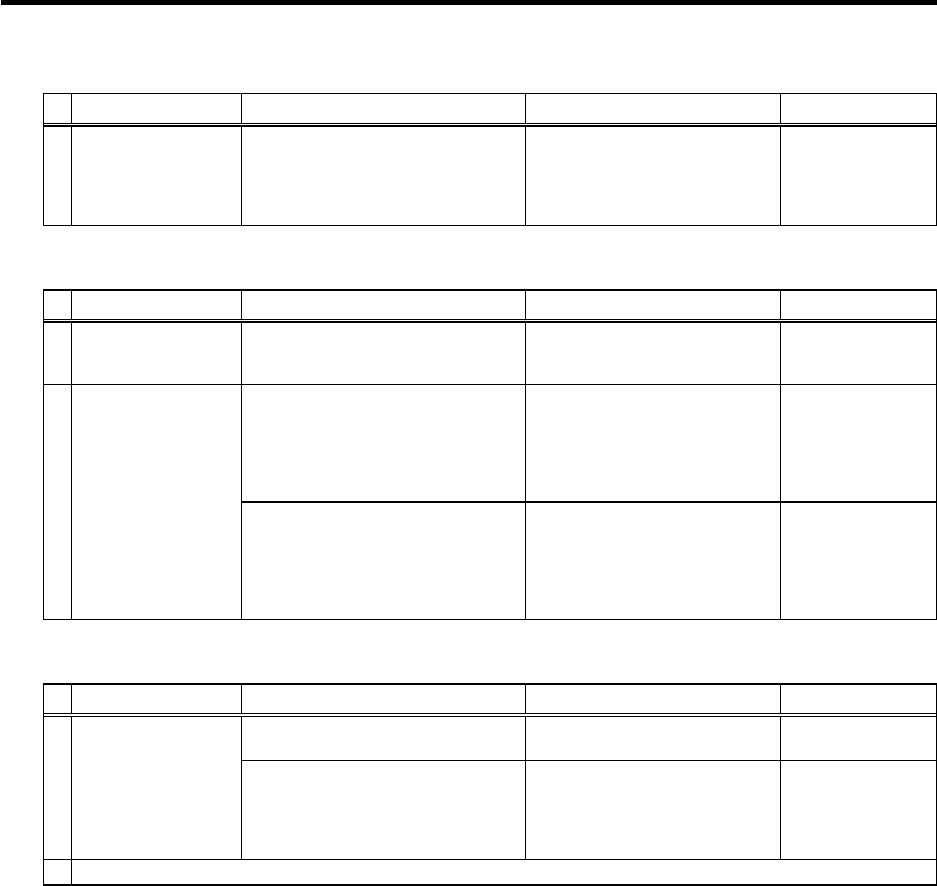

[4] The stopping position does not change even when the position shift parameter is changed.

Cause Investigation item Remedy Remarks

1 Parameter setting

values are incorrect

The position shift was changed to

2048 when the gear ratio between the

spindle and encoder was 1:2 (one

encoder rotation at two spindle

rotations).

If the gear ratio on the left is

established between the spindle

and encoder, the position shift

amount for one spindle rotation is

2048 instead of 4096.

[5] The machine vibrates when stopping.

Cause Investigation item Remedy Remarks

1 Parameter setting

values are incorrect

The gear ratio parameters SP025

(GRA1) to SP032 (GRB4) are

incorrect.

Correctly set SP025 (GRA1) to

SP032 (GRB4).

2 The orientation

adjustment is faulty

The vibration frequency is several Hz. Decrease the position loop gain

parameters SP001 (PGM) and

SP002 (PGE).

Increase the current loop gain for

orientation parameters SP105

(IQGO) and SP106 (IDGO).

The vibration frequency is 10Hz or

more.

Decrease the speed loop gain for

orientation parameters SP098

(VGOP) and SP099 (VGOI).

Decrease the current loop gain for

orientation parameters SP105

(IQGO) and SP106 (IDGO).

[6] The orientation complete signal is not output

Cause Investigation item Remedy Remarks

1 The machine's load is

heavy

The in-position parameter SP004

(OINP) is too small.

Review the in-position range, and

increase SP004 (OINP).

State is improved if delay

compensation control is stopped

during orientation stopping.

(State is improved when changed to

PI control).

Review the values set for the

speed loop gain for orientation

parameters SP098 (VGOP),

SP099 (VGOI) and SP100

(VGOD).

2 Carry out the items for [1] Orientation does not take place (motor keeps rotating).