3. Setup

3 - 59

Standard specifications

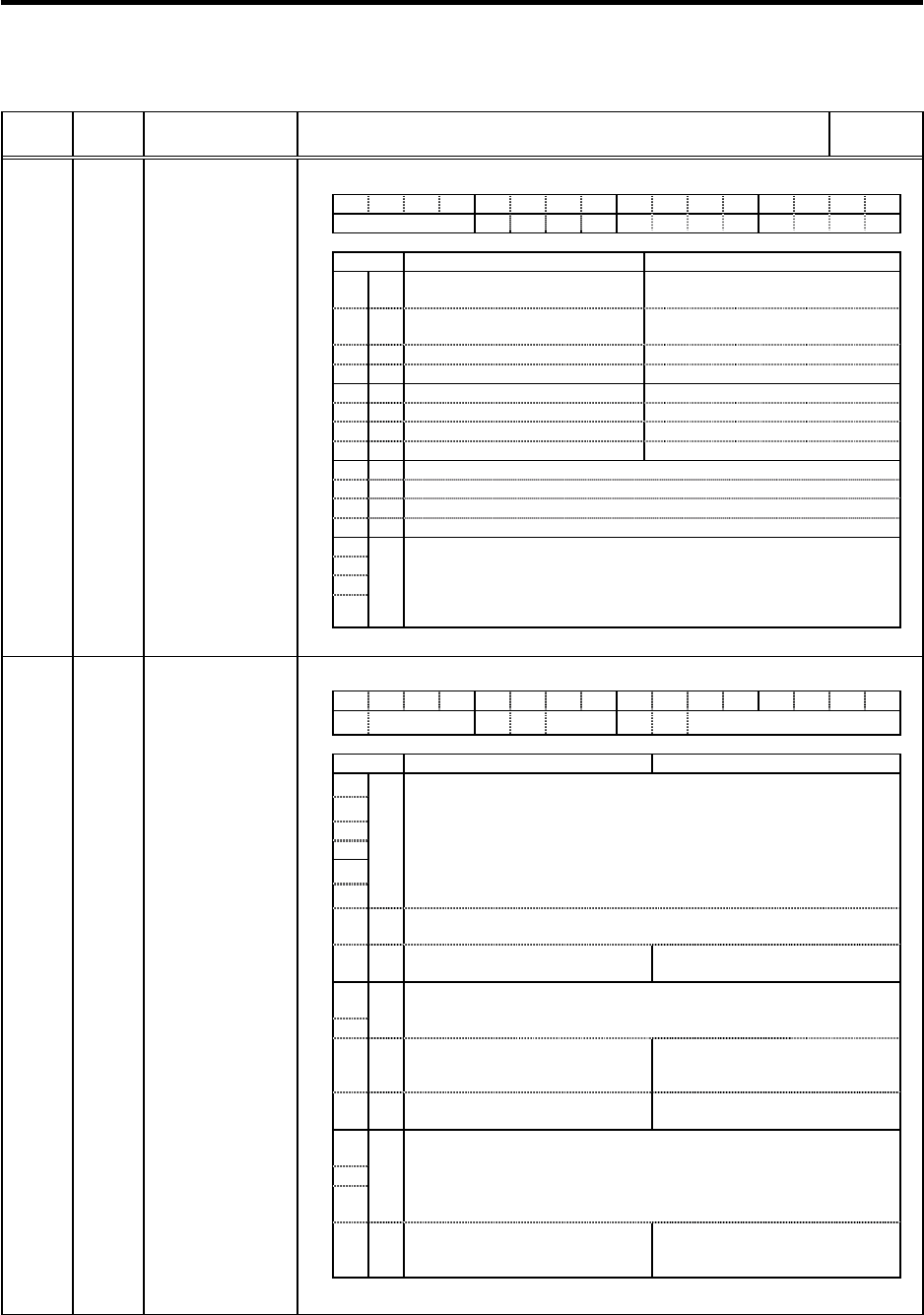

No. Abbrev. Parameter name Explanation

S

etting range

(Unit)

FEDCBA98765 4 3 2 10

ovsn has2 has1

bit Meaning when “0” is set Meaning when “1” is set

0 has1

Setting for normal use.

(Except for HC)

HAS control 1 valid

(HC: High acceleration rate support)

1 has2

Setting for normal use.

(Except for HC)

HAS control 2 valid

(HC: Overshooting support)

2

3

4

5

6

7

8

9

A

B

C

D

E

ovsn

F

Set the non-sensitive band of the overshooting compensation type 3 in

increments of 2m at a time.

In the feed forward control, the non-sensitive band of the model

position droop is set, and overshooting of the model is ignored. Set

2µm (0001) as a standard.

SV034 SSF3

Servo function

selection 3

(Note) Set to “0” for bits with no particular description.

HEX setting

FEDCBA98765 4 3 2 10

clt clG1 cl2n clet cltq iup tdt

bit Meaning when “0” is set Meaning when “1” is set

0

1

2

3

4

5

tdt

Td creation time setting

Set to “0”. (For machine tool builder adjustment)

6iup

Set to “1” when using any of motors from HC152 to HC702 and from

HC153 to HC453.

7 ckab

Setting for normal use No signal 2 (Alarm 21) special

detection

8

Set the retracting torque for collision detection in respect to the

maximum torque of the motor.

9

Cltq

00: 100% 01: 90% 10: 80% (Standard) 11: 70%

Aclet

Setting for normal use The disturbance torque peak of the

latest two seconds is displayed in

MPOS of the servo monitor screen.

B cl2n Collision detection method 2 valid

Collision detection method 2

invalid

C

Collision detection method 1

Set the collision detection level during cutting feed (G1).

D clG1 The G1 collision detection level=SV060*clG1.

E

When clG1=0, the collision detection method 1 during cutting feed

won’t function.

Fclt

Setting for normal use The guide value of the SV059

setting value is displayed in MPOS

of the servo monitor screen.

SV035 SSF4

Servo function

selection 4

(Note) Set to “0” for bits with no particular description.

Parameters with an asterisk * in the abbreviation, such as PC1*, are validated with the NC power turned ON again.