5. Spindle Adjustment

5 - 57

5-3-6 Adjusting the spindle synchronous control

(1) Confirming the default parameters

Confirm that the parameters are correctly set according to the machine specifications. The

parameters are set with the following conditions for spindles used for synchronous control.

(a) Position loop gain

The same value must be set for the spindle drive units used for synchronous control.

Spindle synchronous position loop gain : SP010

Spindle synchronous position loop gain 2 : SP189

Spindle synchronous position loop gain 3 : SP190

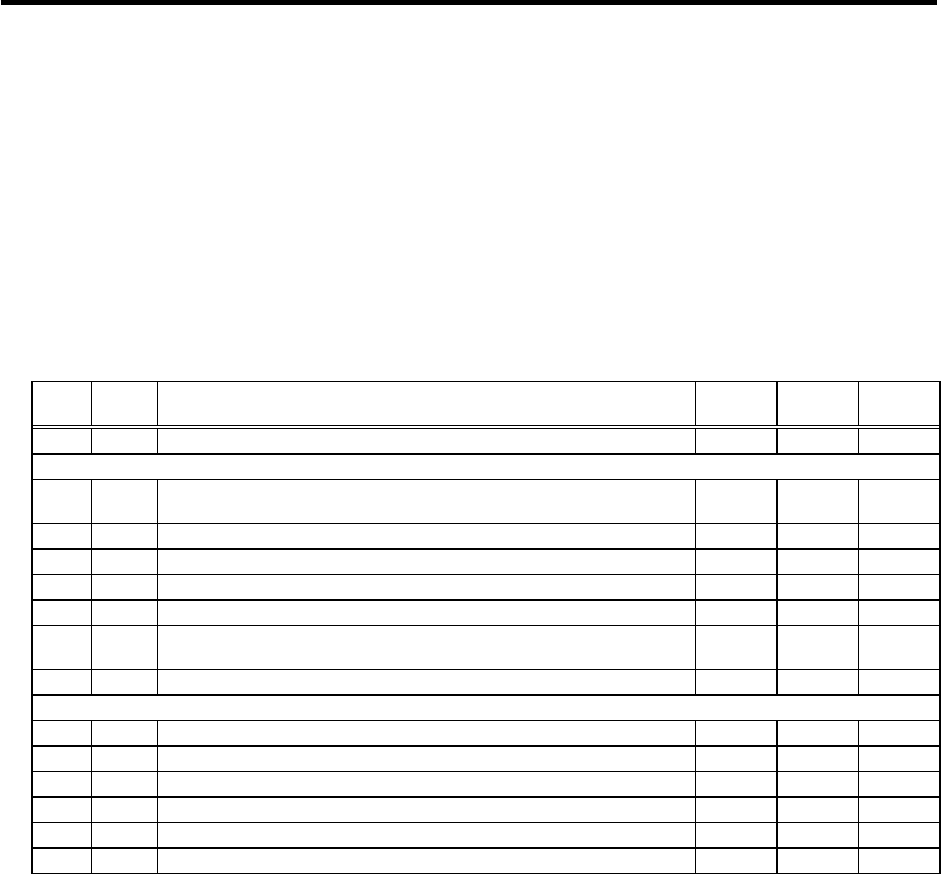

<Spindle parameters>

No. Abbr. Parameter name Unit

Setting

range

Standard

value

SP010 PGS Spindle synchronization position loop gain rad/s 1 to 100 15

SP177 SPECS* Spindle synchronous specifications HEX

0000 to

FFFF

0000

SP178 VGSP* Spindle synchronous speed loop gain proportional term 0 to 1000 63

SP179 VGSI* Spindle synchronous speed loop gain integral term 0 to 1000 60

SP180 VGSD* Spindle synchronous speed loop gain delay advance term 0 to 1000 15

SP181 VCGS* Spindle synchronous Target value of variable speed loop proportional gain % 0 to 100 100

SP182 VCSS*

Spindle synchronous Change starting speed of variable speed loop

proportional gain

r/min 0 to 32767 0

SP183 SYNV Spindle synchronous Sync matching speed r/min 0 to 1000 20

SP185 SINP Spindle synchronous In-position width 1/16 deg 1 to 2880 16

SP186 SODR* Spindle synchronous Excessive error width (1pulse=0.088deg) pulse 0 to 32767 32767

SP187 IQGS* Spindle synchronous Current loop gain magnification 1 % 0 to 1000 100

SP188 IDGS* Spindle synchronous Current loop gain magnification 2 % 0 to 1000 100

SP189 PG2S Spindle synchronous Position loop gain 2 rad/s 0 to 999 0

SP190 PG3S Spindle synchronous Position loop gain 3 rad/s 0 to 999 0