3. Setup

3 - 104

3-6 Initial adjustment of the spindle PLG

3-6-1 Adjusting the PLG installation

The PLG (spindle motor speed detector) mounted on the

Mitsubishi framed spindle motor is shipped from Mitsubishi

in the adjusted state. If there are no particular problems,

carry out automatic adjustment "3-6-2 Automatic

adjustment of Z phase" and "3-6-3 Automatic adjustment of

motor end PLG" according to the spindle system.

When using the spindle end PLG for simple C-axis control

or the built-in spindle, the PLG detector is installed by the

user, so the PLG sensor's gap and output signal must be

adjusted with the following procedures. After installing and

adjusting these, carry out automatic adjustment of the PLG

according to each system.

Install the PLG and then adjust following the procedures on

the right. The output signal waveform can be retrieved from

the check terminal on the PCB. Measure the waveform with

an oscilloscope. The A/B phase output signal and the Z

phase pulse width can be adjusted with the volume (VR1 to

VR5) on the PCB. (The pulse width has been adjusted at

shipment, and normally does not need to be adjusted.)

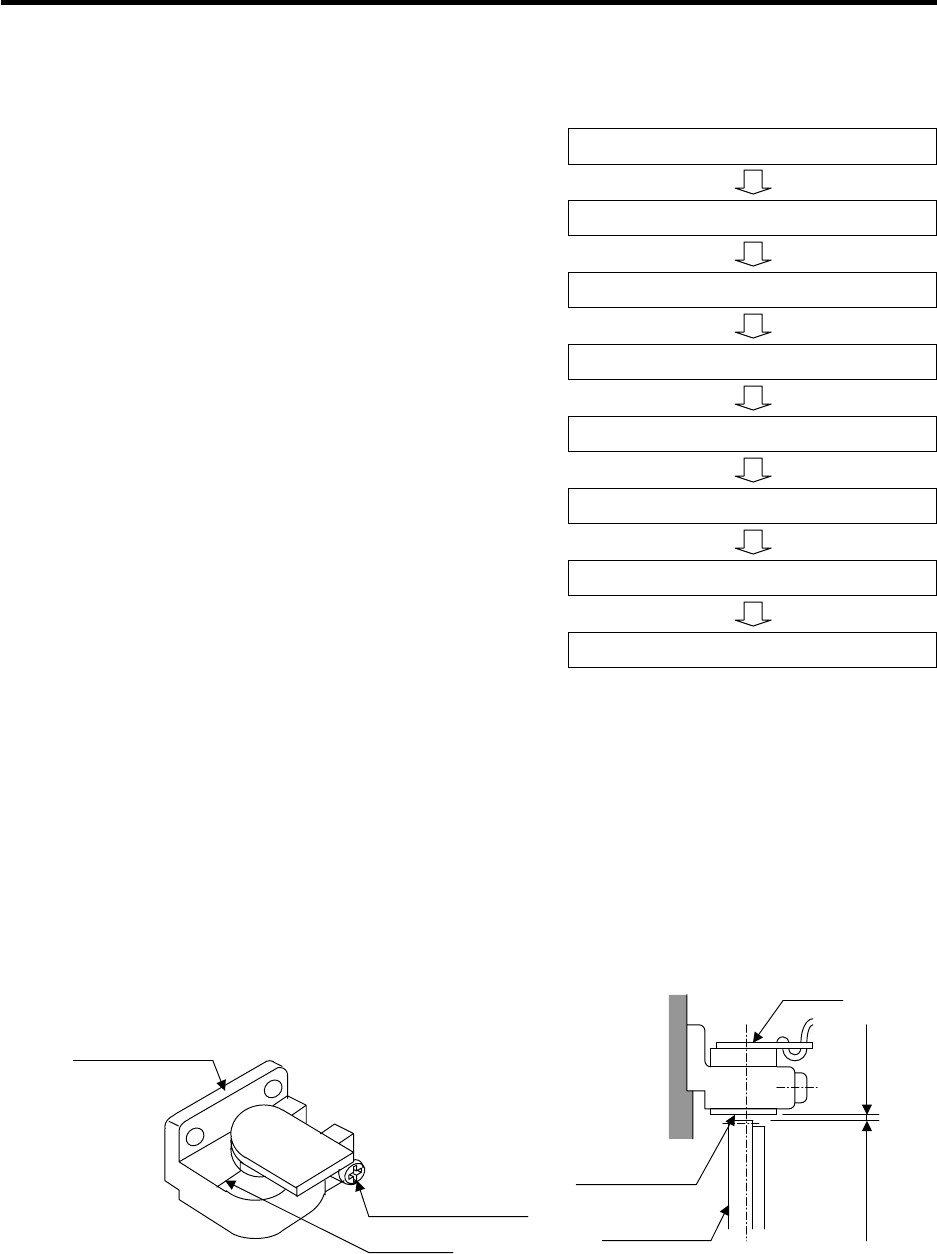

(1) Checking the gap

Check that the gap between the sensor detection surface and detection gear circumference is

within 0.15±0.01mm as shown below. The gap is adjusted before shipment, but an error could

occur due to the effect of the dimensional difference of the notched fitting section provided for

installation, or the dimensional difference of the detection gears' outer diameter. If deviated from

the above range, adjust the gap following the section "(2) Adjusting the gap".

Sensor section Gap with detection gear

(1) Checking the gap

(2) Adjusting the gap

(3) Checking the A and B phase output signal

(4) Adjusting the A and B phase output signal

(5) Checking the Z phase pulse width

(6) Adjusting the Z phase pulse width

(7) Checking the Z phase and A phase difference

(8) Adjusting the Z phase and A phase difference

Flow of PLG installation and adjustment

Senso

r

Detection gear

circumference

Ga

p

0.15±0.01mm

Detection gear

Sensor detection

surface

Markin

g

line

Sensor installation

seat

Sensor fixing screw