2. Wiring and Connection

2 - 43

2-7-2 Spindle coil changeover

There are spindle motors capable of coil changeover control, which enables favorable characteristics to

be attained from low speeds to high speeds by changing two types or three types (only for

MDS-C1-SPM) of coils.

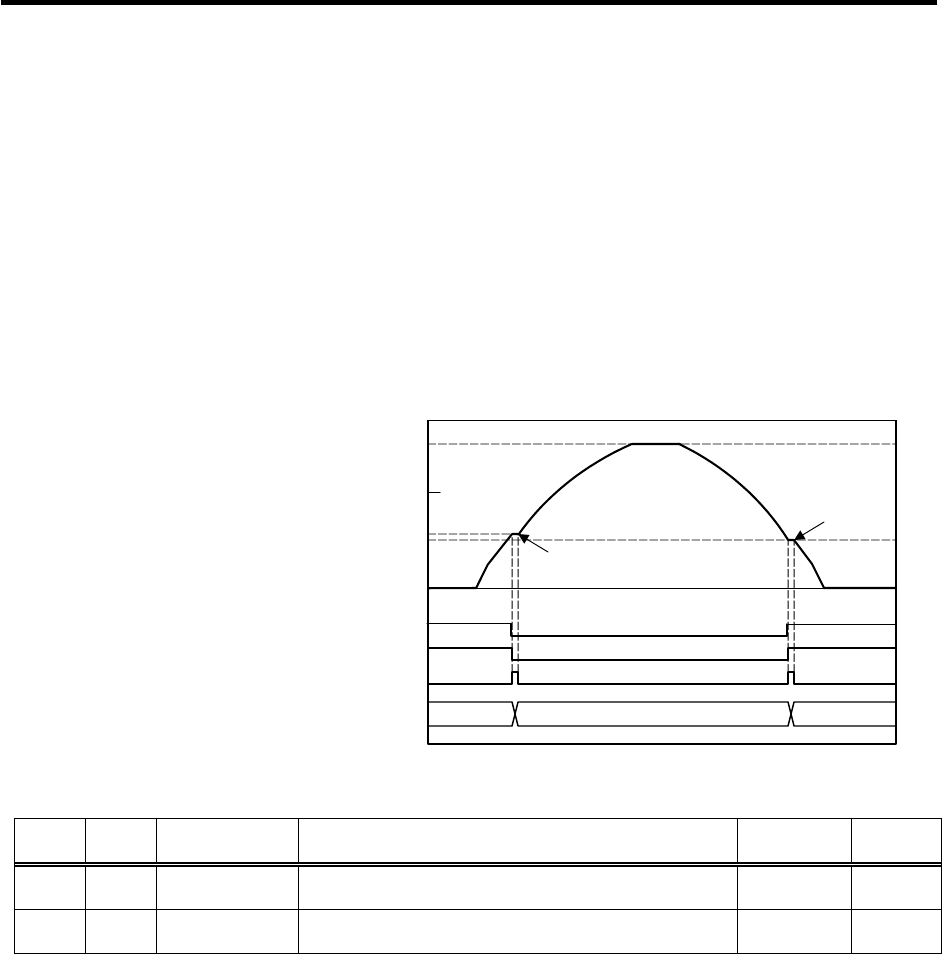

(1) Coil changeover control

The speed at which to change the coils is detected by the spindle drive according to the value set

with spindle parameter SP020. This is conveyed to the NC with a speed detection (SD) signal. The

NC judges the other conditions (coil fixed, etc.), and issue a coil changeover command to the

spindle drive with the L coil selection command (LCS).

To prevent the contactor from varying, the hysteresis set with SP047 is applied on the speed when

changing from the low-speed coil to the high-speed coil and the high-speed coil to the low-speed

coil.

Speed detection (SD1) [SP→NC]

L coil selection command (LCS) [NC→SP]

Changing coil (MKC) [SP→NC]

Contactor changeover

0

2000

Time

6000

Spindle motor speed

(r/min)

Low-speed coil

4000

(SP020+SP047

High-speed coil

Low-speed coil

SP020

Spindle motor coil changeover control

No. Abbrev. Parameter name Description Setting range

Standard

value

SP020 SDTS* Speed detection

set value

Set the motor speed of which speed detection 1 output is

performed. Usually, the setting value is 10% of SP017 (TSP).

0 to 32767

(r/min)

600

SP047 SDTR* Speed detection

reset value

Set the reset hysteresis width for a speed detection set value

defined in SP020 (SDTS).

0 to 1000

(r/min)

30