5. Spindle Adjustment

5 - 3

5-1-2 Setting the output data

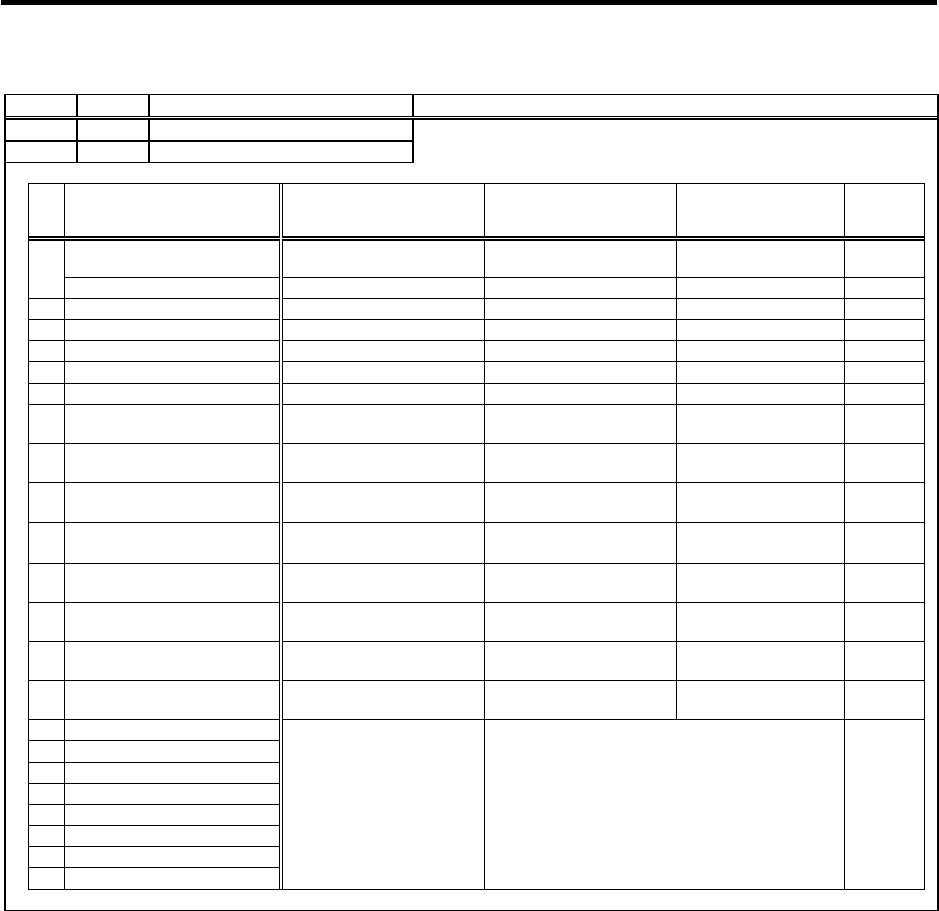

No. Abbr. Parameter name Explanation

SP253 DA1NO

D/A output channel 1 data No.

Input the No. of the data to be output to each D/A output channel.

SP254 DA2NO

D/A output channel 2 data No.

No. Output data Original data unit

Output magnification

standard setting value

(SP255, SP256)

Output unit for

standard setting

Output

cycle

ch1: Speedometer output 10V=max. speed (Zero=0V) 0

Depends on maximum

speed

3.55ms

0

ch2: Load meter output 10V=120% load (Zero=0V) 0 30-minute rating 12%/V 3.55ms

1 –

2 Current command Rated 100%=4096 8 30-minute rating 20%/V 3.55ms

3 Current feedback Rated 100%=4096 8 30-minute rating 20%/V 3.55ms

4 Speed feedback r/min 13 500rpm/V 3.55ms

5 –

6

Position droop

(lower order 16bit)

0.001deg=64 10 (10.24) 0.01deg/V 888µs

7

Position droop

(higher order 16bit)

1deg=(64000÷65536)

671 10deg/V 888µs

8

Feedrate (F∆T)

(lower order 16bit)

0.001deg=64

173

(at 3.5ms communication)

10deg/min/V 888µs

9

Feedrate (F∆T)

(higher order 16bit)

1deg=(64000÷65536)

629

(at 3.5ms communication)

500rpm/V 888µs

10

Position command

(lower order 16bit)

0.001deg=64 10 (10.24) 0.01deg/V 888µs

11

Position command

(higher order 16bit)

1deg=(64000÷65536)

19 (18.64) 360deg/V 888µs

12

Position FB

(lower order 16bit)

0.001deg=64 10 (10.24) 0.01deg/V 888µs

13

Position FB

(higher order 16bit)

1deg=(64000÷65536)

19 (18.64) 360deg/V 888µs

80 Control input 1

81 Control input 2

82 Control input 3

83 Control input 4

84 Control output 1

HEX Bit correspondence 3.55ms

85 Control output 2

86 Control output 3

87 Control output 4