3. Setup

3 - 70

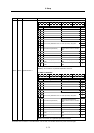

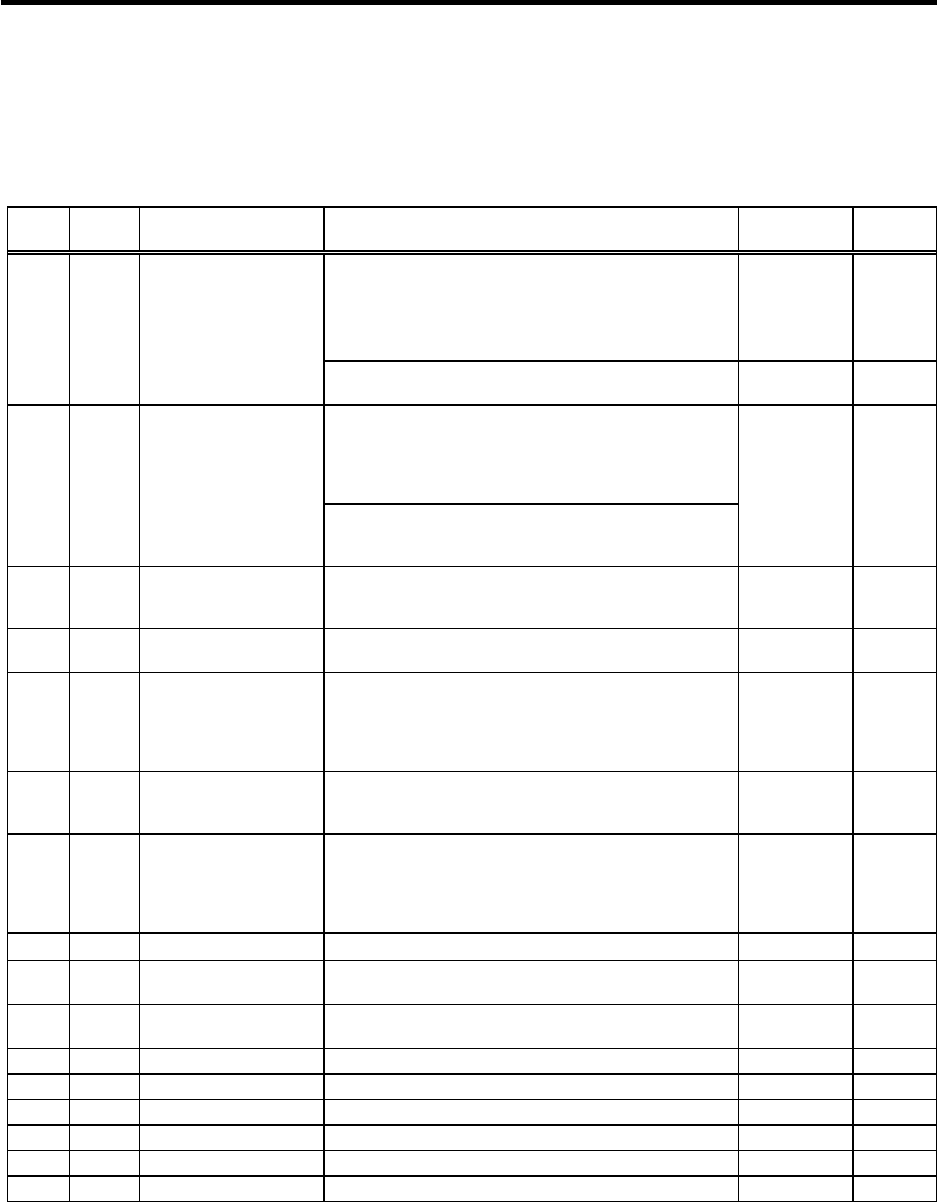

3-5-2 List of spindle parameters

These parameters are sent to the spindle drive unit when the NC power is turned ON. The standard

parameters are designated with the "Spindle parameter setting list" enclosed when the spindle motor is

delivered. There may be cases when the machine specifications are unclear, so the parameters

determined by the machine specifications should be confirmed by the user.

No. Abbr. Parameter name Details

Setting range

(Unit)

Standard

setting

<For MDS-C1-SP/SPH/SPM>

The orientation time will be shorter when the value is

increased, and the servo rigidity will increase. On the

other hand, the vibration will increase, and the machine

will sway easily.

0 to 1000

(0.1 rad/s)

100

SP001 PGM

Magnetic sensor, motor

PLG orientation position

loop gain

<For MDS-C1-SPX/SPHX>

Not used. Set "0".

0 0

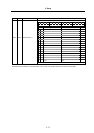

<For MDS-C1-SP/SPH/SPM>

The orientation time will be shorter when the value is

increased, and the servo rigidity will increase. On the

other hand, the vibration will increase, and the machine

will sway easily.

SP002 PGE

Encoder orientation

position loop gain

<For MDS-C1-SPX/SPHX>

Set the position loop gain for spindle end PLG

orientation.

0 to 1000

(0.1 rad/s)

100

SP003 PGC

Position gain during

C-axis non-cutting

Set the position loop gain for the C-axis non-cutting mode.

During non-cutting (rapid traverse, etc.) with the C axis

control, this position loop gain setting is valid.

0 to 100

(rad/s)

15

SP004 OINP

Orientation in-position

width

Set the position error range in which an orientation

completion signal is output.

1 to 2880

(1/16°)

16

SP005 OSP*

Orientation mode

speed clamp value

Set the motor speed limit value to be used when the

speed loop is changed to the position loop in orientation

mode.

When this parameter is set to "0", SP017 (TSP) becomes

the limit value.

0 to 32767

(r/min)

0

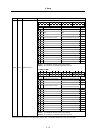

SP006 CSP

Orientation mode

deceleration rate

As the set value is larger, the orientation time becomes

shorter. However, the machine becomes likely to

overshoot.

1 to 1000 20

SP007 OPST

Position shift amount for

orientation

Set the stop position for orientation.

(1) Motor PLG and spindle end detector

Set a value obtained by dividing 360° by 4096.

(2) Magnetic sensor orientation

Divide -5°C to +5° by 1024, and set 0° as "0".

(1)

0 to 4095

(2)

-512 to 512

0

SP008

Not used. Set

"0".

0 0

SP009 PGT

Synchronous tap

position loop gain

Set the spindle position loop gain for synchronous

tapping.

1 to 100

(rad/s)

15

SP010 PGS

Spindle synchronization

position loop gain

Set the spindle position loop gain for spindle

synchronization.

1 to 100

(rad/s)

15

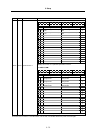

SP011 Not used. Set "0". 0 0

SP012 Not used. Set "0". 0 0

SP013 Not used. Set "0". 0 0

SP014 Not used. Set "0". 0 0

SP015 Not used. Set "0". 0 0

SP016 Not used. Set "0". 0 0

Parameters with an asterisk * in the abbreviation, such as OSP*, are validated with the NC power turned ON again.