6. Troubleshooting

6 - 9

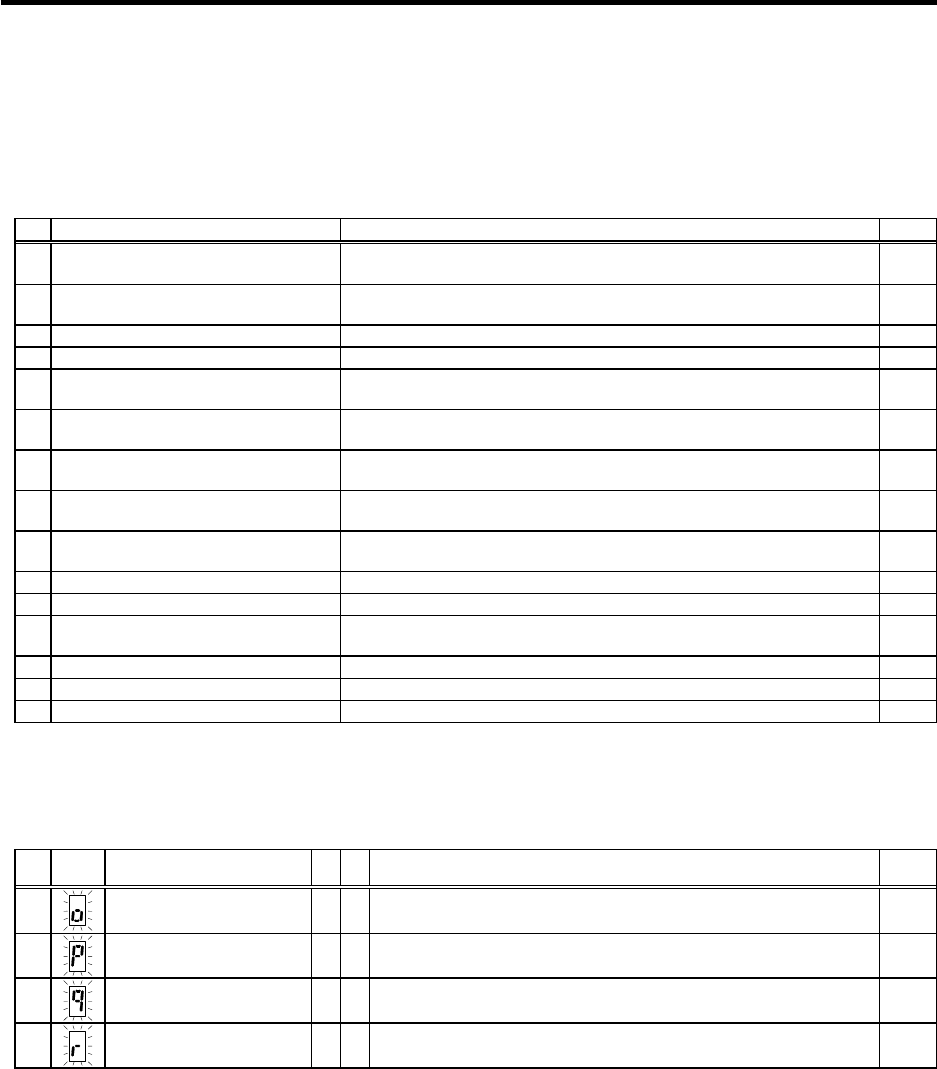

6-2-2 List of warnings

When a warning occurs, a warning No. will appear on the NC monitor screen and with the LEDs on the

front of the drive unit. Check the warning No., and remove the cause of the warning by following this

list.

Drive unit warnings

No. Alarm name Warning details Reset

90 Detector, initial communication error Initial communication with the absolute position linear scale was not

possible.

PR

91 Detector, communication error An error was detected in the communication with the detector for the

absolute position detection system.

*

92 Detector, protocol error An error was detected in the data for the absolute position detection system. *

93 Initial absolute position fluctuation The position data fluctuated when creating the initial absolute position. PR

96 MP scale feedback error An excessive deviation was detected in the motor end detector and MP

scale feedback data for the MP scale absolute position detection system.

*

97 MP scale offset error An error was detected in the offset data received from the MP scale for the

MP scale absolute position detection system.

PR

9E Absolute position detector, multi-

rotation counter error

An error was detected in the multi-rotation counter for the absolute position

detector. The absolute position cannot be compensated.

*

9F Battery voltage drop The voltage of the battery supplying to the absolute position detector has

dropped. The absolute position data is held.

*

A8 Turret indexing error warning The commanded turret indexing position shift amount is not within the

specified range.

*

A9 Orientation feedback error warn Retrying during an orientation feedback error. *

E1 Overload warning The overload detection level is 80% or more. *

E3 Absolute position counter warning A deviation was detected in the absolute position data and absolute position

data.

*

E4 Parameter error warning A parameter exceeding the setting range was set. *

E6 Control axis removal warning Control axis removal was commanded. *

E7 CNC emergency stop Emergency stop was input from the NC. *

(Note 1) Servo and spindle motor do not stop when the warning occurs.

(Note 2) When an emergency stop is input, servo and spindle motor decelerate to a stop.

(When SV048, SV055 or SV056 is set for servo and when SP038/bit 0=1is set.)

Power supply warnings

No.

LED

display

Alarm name CV CR Warning details Reset

E8

Auxiliary regeneration

frequency over

{

Regeneration at the power supply performance limit is occurring

frequently.

*

E9

Instantaneous power failure

warning

{

An instantaneous power failure occurred. NR

EA

External emergency stop

{

The external emergency stop signal was input. *

EB

Over-regeneration warning

{

The over-regeneration level is 80% or more. *

(Note) Servo and spindle motor do not stop when the warning occurs.

Resetting methods

* : Automatically reset once the cause of the warning is removed.

NR : Reset with the NC RESET button. This warning can also be reset with the PR and AR resetting conditions.

PR : Reset by turning the NC power ON again. This warning can also be reset with the AR resetting conditions.

When the control axis is removed, this warning can be reset with the NC RESET button. (Excluding warning 93.)