3. Setup

3 - 61

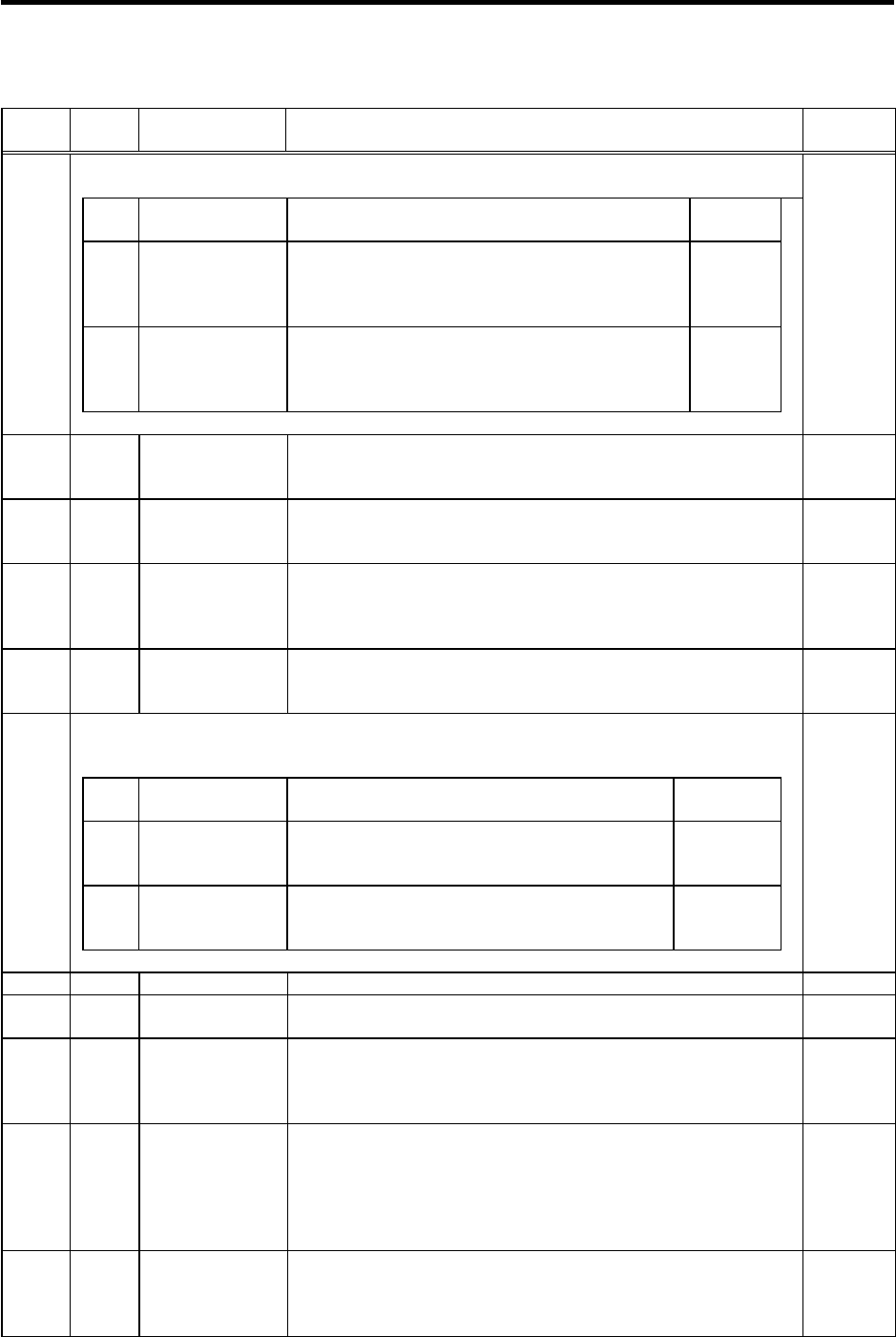

Standard specifications

No. Abbrev. Parameter name Explanation

Setting range

(Unit)

For SV040, the hex. value’s higher order 8bits and lower order 8bits are used for different functions.

“Setting value of SV040” = (Icy*256) + LMCT

Abbrev. Parameter name Explanation

Setting range

(Unit)

LMCT

(Low

order)

Lost motion

compensation dead

band

Set the dead band of the lost motion compensation in the

feed forward control.

When “0” is set, the actual value that is set is 2m.

Adjust by increasing by 1m at a time.

0 to 100

(µm)

Icy

(High

order)

Current bias 2

Normally, set to “40” if you use HC202 to HC902, HC203

to HC703.

Use this in combination with SV030 and the high order

8bits of SV045.

0 to 127

SV040

0 to 32767

SV041 LMC2

Lost motion

compensation 2

Set this with SV016 (LMC1) only when you wish to set the lost motion

compensation amount to be different depending on the command directions.

Set to “0” as a standard.

-1 to 200

(Stall [rated]

current %)

SV042 OVS2

Overshooting

compensation 2

Set this with SV031 (OVS1) only when you wish to set the overshooting

compensation amount to be different depending on the command directions.

Set to “0” as a standard.

-1 to 100

(Stall [rated]

current %)

SV043 OBS1

Disturbance

observer filter

frequency

Set the disturbance observer filter band.

Set to “100” as a standard.

To use the disturbance observer, also set SV037 (JL) and SV044 (OBS2).

When not using, set to “0”.

0 to 1000

(rad/s)

SV044 OBS2

Disturbance

observer gain

Set the disturbance observer gain. The standard setting is “100” to “300”.

To use the disturbance observer, also set SV037 (JL) and SV043 (OBS1).

When not using, set to “0”.

0 to 500

(%)

For SV045, the hexadecimal value's higher order 8 bits and lower order 8 bits are used for different

functions.

“Setting value of SV045” = (Icy

× 256) + LMCT

Abbrev. Parameter name Explanation

Setting range

(Unit)

TRUB

(Low

order)

Frictional torque

When you use the collision detection function, set the

frictional torque.

0 to 100

(Stall [rated]

current %)

Ib1

(High

order)

Current bias 3

Normally set to “0”.

Use this in combination with SV030 and the high order

8bits of SV040.

0 to 127

SV045

0 to 32767

SV046 Not used. Set to "0". 0

SV047 EC

Inductive voltage

compensation gain

Set the inductive voltage compensation gain. Set to “100” as a standard.

If the current FB peak exceeds the current command peak, lower the gain.

0 to 200

(%)

SV048 EMGrt

Vertical axis drop

prevention time

Input a length of time to prevent the vertical axis from dropping by delaying

Ready OFF until the brake works when the emergency stop occurs.

Increase the setting by 100msec at a time and set the value where the axis

does not drop.

0 to 20000

(ms)

SV049 PGN1sp

Position loop gain 1

in spindle

synchronous control

Set the position loop gain during the spindle synchronous control

(synchronous tapping, synchronous control with spindle/C axis).

Set the same value as the value of the spindle parameter, position loop gain

in synchronous control.

When performing the SHG control, set this with SV050 (PGN2sp) and

SV058 (SHGCsp).

1 to 200

(rad/s)

SV050 PGN2sp

Position loop gain 2

in spindle

synchronous control

Set this with SV049 (PGN1sp) and SV058 (SHGCsp) if you wish to perform

the SHG control in the spindle synchronous control (synchronous tapping,

synchronous control with spindle/C axis).

When not performing the SHG control, set to “0”.

0 to 999

(rad/s)

Parameters with an asterisk * in the abbreviation, such as PC1*, are validated with the NC power turned ON again.