5. Spindle Adjustment

5 - 33

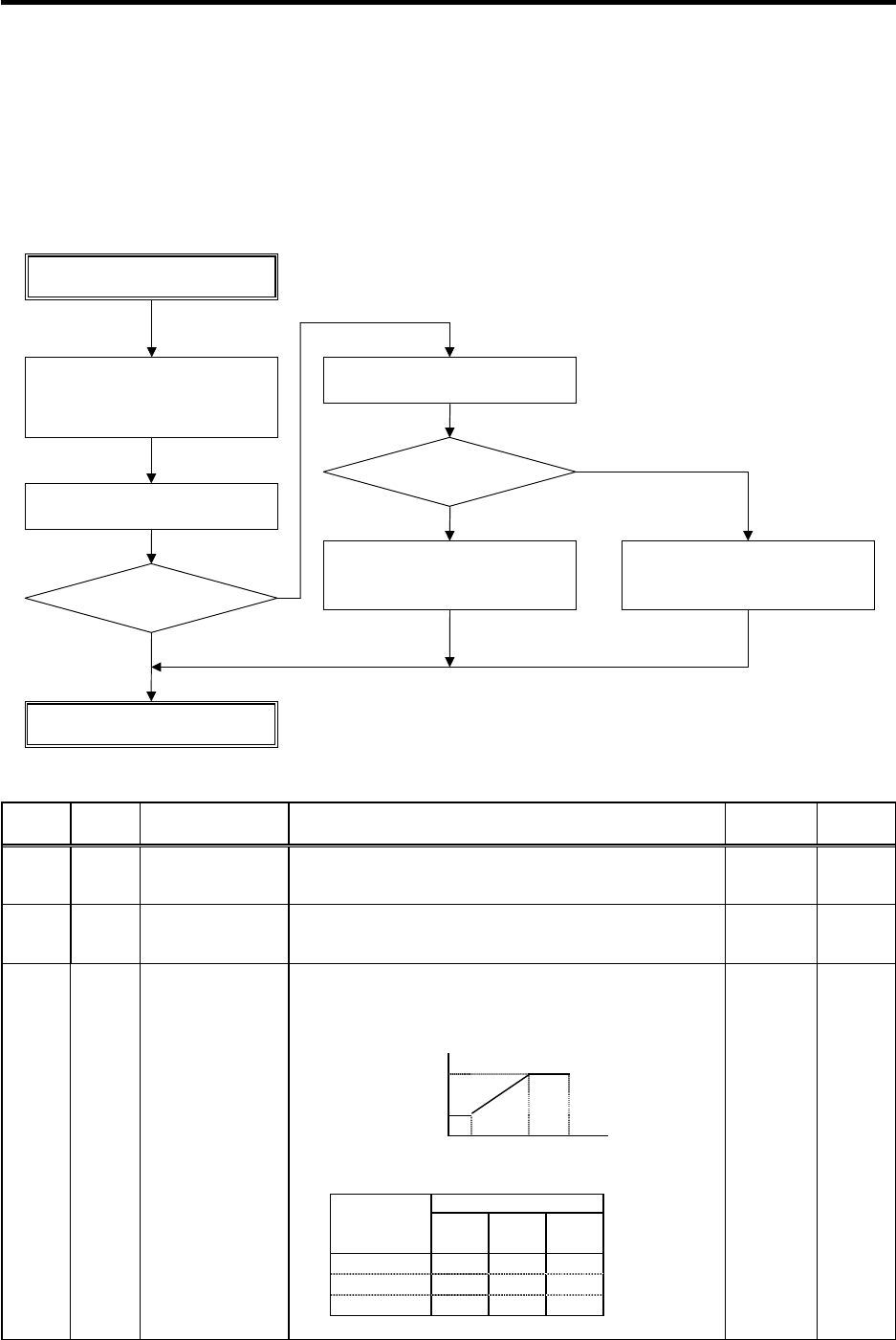

(7) Adjusting current loop gain

Although the default setting value is usually appropriate, an adjustment may be required if slight

vibration occurs at high spindle motor rotating. In such cases, adjust the target value of variable

current loop gain (SP069) parameter setting while observing the current waveform in the

high-speed range. Adjust until the output waveform to the spindle motor stabilizes.

Set the change starting/ending speed of variable current loop gain (SP067 and SP068) parameters

in accordance with the motor's maximum rotation speed.

No. Abbr. Parameter name Details

Setting

range

Standard

SP067 VIGWA* Change starting

speed of variable

current loop gain

Set the speed where the current loop gain change starts. 0 to 32767

(r/min)

0

SP068 VIGWB* Change ending

speed of variable

current loop gain

Set the speed where the current loop gain change ends. 0 to 32767

(r/min)

0

Set the magnification of current loop gain (torque component

and excitation component) for a change ending speed defined

in SP068 (VIGWB).

When this parameter is set to "0", the magnification is 1.

SP069×(1/16) fold

1-fold

SP067 SP068 SP017

SP069 VIGN* Target value of

variable

current loop gain

Setting value SP017(TSP)

Maximum motor

speed

SP067

(VIGWA)

SP068

(VIGWB)

SP069

(VIGN)

0 to 6000 0 0 0

6001 to 8000 5000 8000 45

8001 or more 5000 10000 64

0 to 32767

(1/16-fold)

0

Adjusting SP069

Vibration in current waveform?

SP069 adjustment completed

NO

NO

Measure acceleration/deceleration

waveform at high speed

Increase SP069 by +8.

YES

YES

Default settings in accordance

with motor's max. rotation speed

(SP067, SP068, SP069)

Improved?

A

djust by increasing the SP069

setting in increments of 8

A

djust by decreasing the SP069

setting in decrements of 8