3. Tool Offset (L system)

3.2 Tool Length Data

I-92

Refer to "3 (II). Tool Offset (M system)" for M system.

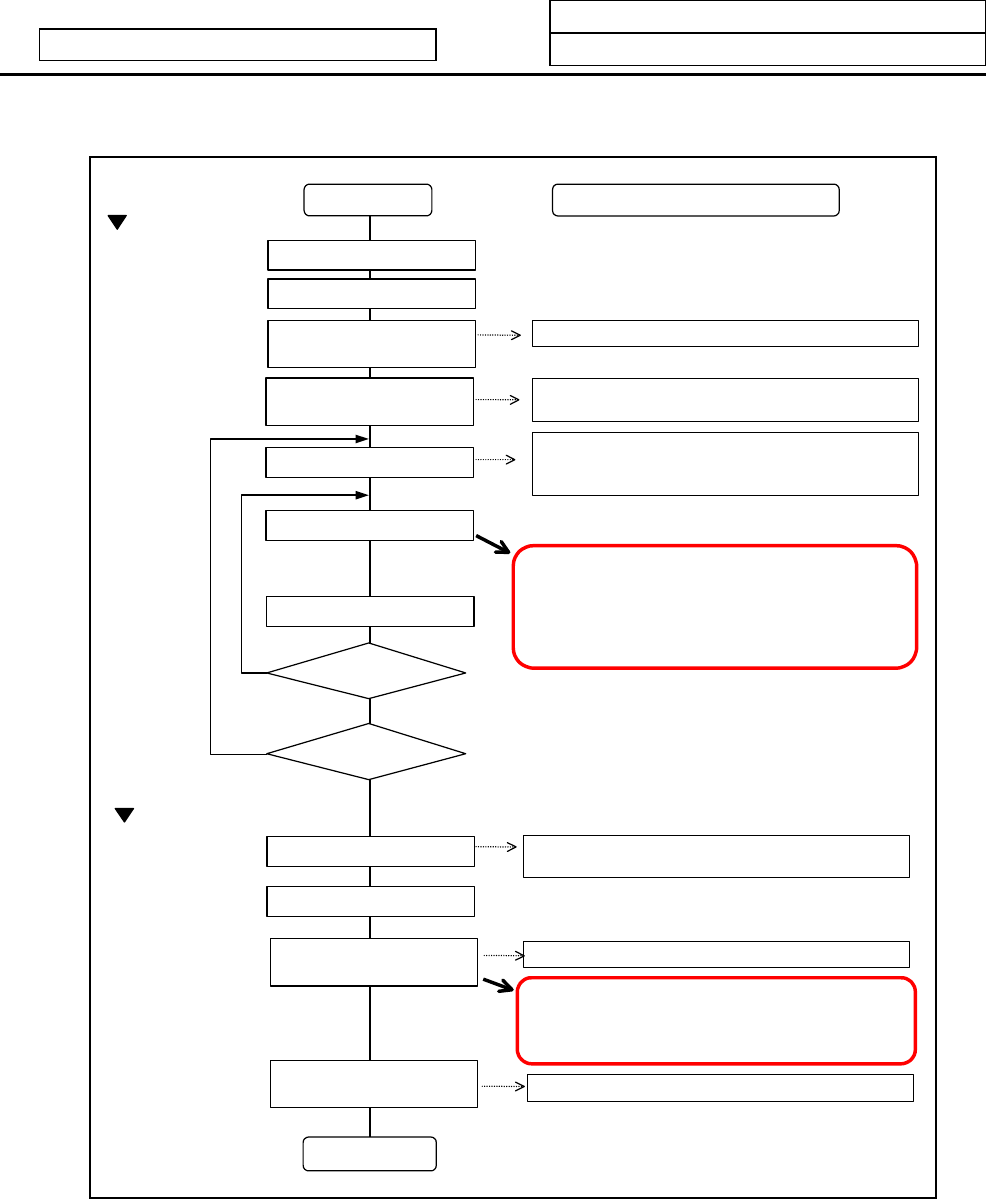

(3) Operation flow

Start of operation

Measure other axes?

Zero point return

End of operation

Select manual mode

Turn tool measurement mode

[TLMS] ON

Set No. of tool to be measured

Contact tool against sensor

Retract tool

Set measurement basic

value

Select tool

Cut workpiece edges

Input workpiece

measurement signal

Turn tool measurement mode

[TLMS] OFF

Measure other tools?

Yes

No

Yes

No

Turn ON Y229 (tool measurement mode).

Preset the following axis specification parameter as the

sensor position. #2015 tlml–, #2016 tlml+

Turn OFF Y229 (tool measurement No.)

Turn ON Y329 (workpiece measurement No.)

Set the compensation No. of the tool to be measured in

the R register.

Tool No.: R2970, Wear data compensation No.: R186

Set the compensation No. of the tool to be used for

cutting in the R register.

The tool length offset amount is automatically calculated

from the contacted position, and is stored in the tool

compensation amount memory.

Tool compensation amount = Machine coordinate value

– Measurement basic value (Sensor position)

The wear amount is cleared after measurement.

The Z axis workpiece coordinate offset will be measured

and set in the external workpiece offset.

Workpiece coordinate offset = Machine coordinate value

– Tool compensation data

Interface and operation with NC

♦

Do not move the tool in the Z axis direction after cutting.

♦

The axis movement will stop, and can be moved only in

the direction away from the sensor.

External workpiece offset

♦

The tool compensation amount is measured one axis at a time.

Tool compensation amount