8. Maintenance Functions

8.1 Data Input/Output Function

III-57

8. Maintenance Functions

The machining programs, parameters and tool data, etc., are saved in the memory. However, these

contents could be lost due to the battery life, etc. To avoid total loss, save the machining programs, tool data

and parameters in an input/output device.

8.1 Data Input/Output Function

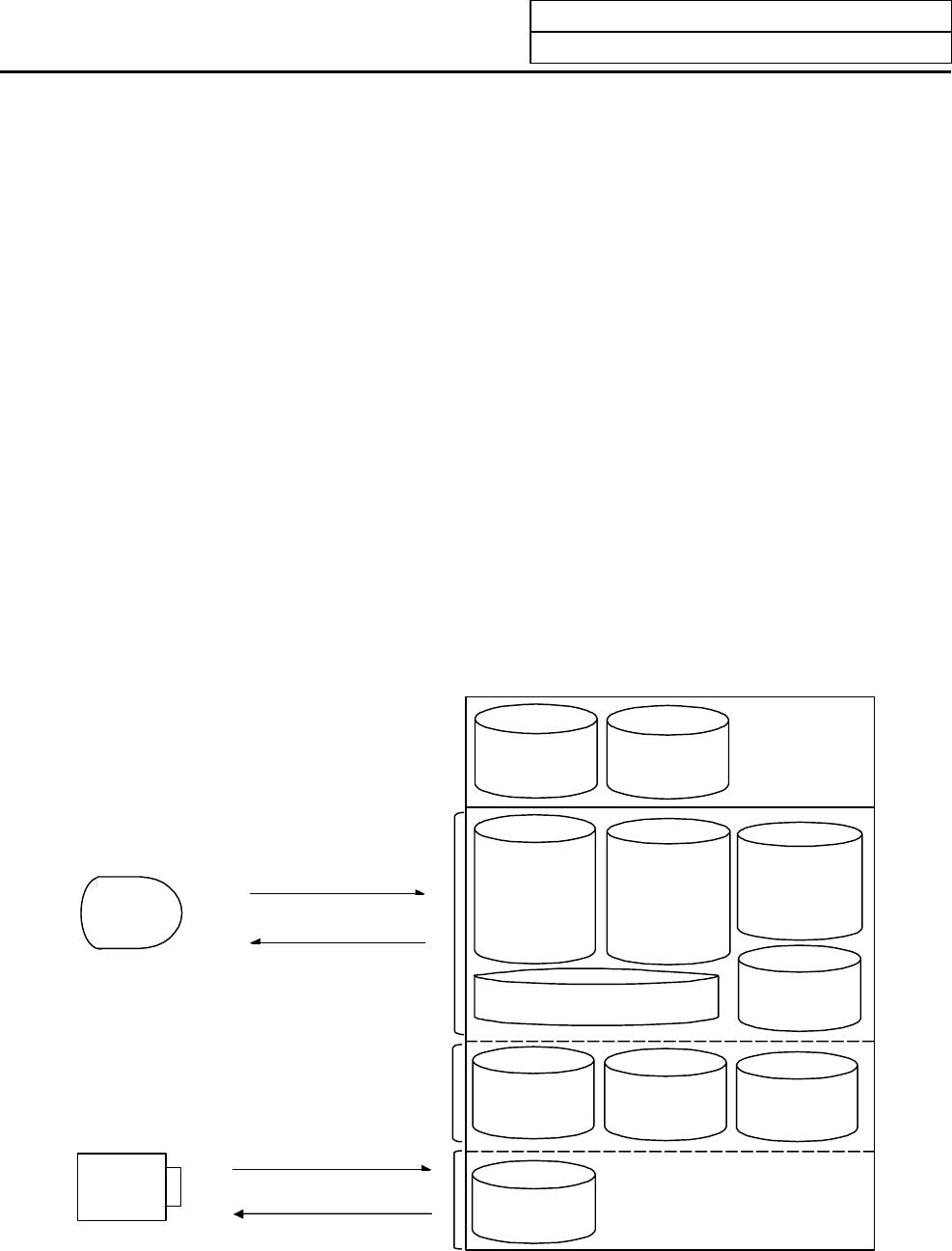

The data can be collectively input/output or collated in the data input/output screen. This function can be

used to protect data and investigate failure causes at the customer premises. It can handle three types of

data shown below. Hex data is converted and output in the ISO/EIA format. Individual data items can also

be input/output or collated separately. This function is valid only while the user PLC is halted.

1. Table data: The data area is reserved in advance.

Parameter (system, common, axis, machine error)

PLC data (PLC timer, PLC counter, PLC constants, bit selection, ATC data, axis control)

Work offset data

Backup data (PLC latch relay, PLC switch, program No.)

2. File data: The file format is required before data input.

Tool offset data

Common variables

Tool life control data

3. PLC program data: PLC program area data

Ladder (ROM: Ladder, message)

Screen

Setting

Display

RS-232C device

Input

Output

PLC

ladder

Tool offset

Common

variables

Tool life

PLC axis

parameter

PLC data PLC timer,

PLC counter

Backup data

PLC switch,

latch relay,

program No.

R register

PLC constant,

bit selection,

A

TC data, user

backup

Parameter

table

System,

common axis,

machine error,

work, offset

Fixed cycle

program

Machining

program

1

2

3