3. Tool Offset (L system)

3.3 Tool Nose Data

I-97

Refer to "3 (II). Tool Offset (M system)" for M system.

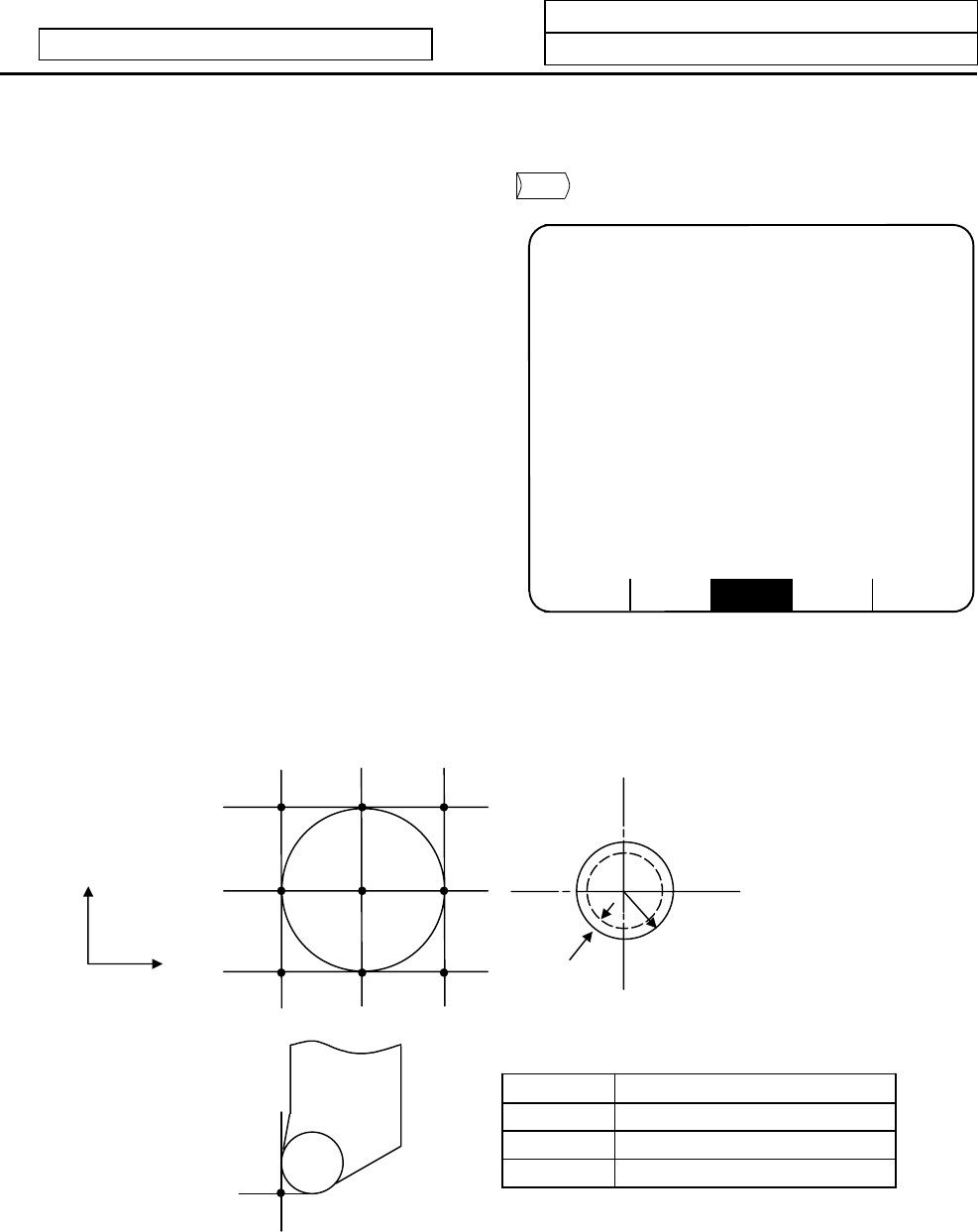

3.3 Tool Nose Data

The NOSE-R screen will appear when the menu key

NOSE-R

is pressed.

T-OFSET T-DATA NOSE-R LIFE MENU

[NOSE - R] TOOL 3.1/4

#

1 R 5.000 r 0.045 P 3

2 R 10.000 r 0.099 P 8

3 R 6.000 r 0.099 P 2

4 R 0.000 r 0.000 P 3

5 R 0.000 r 0.000 P 3

6 R 0.000 r 0.000 P 3

7 R 0.000 r 0.000 P 3

8 R 0.000 r 0.000 P 3

9 R 0.000 r 0.000 P 3

10 R 0.000 r 0.000 P 3

# ( ) R ( ) r ( ) P ( )

Set the tool nose radius R (nose R), wear r, and tool nose point for each tool used. When the tool nose R

compensation (G41, G42, G46) command is given, the tool nose is assumed to be a half-circular arc with

radius R (R + r) corresponding to the tool No. Compensation is then carried out so that the half-circular arc

contacts the designated machining program path.

Data Function

P0 to P8 Tool nose point

R Tool radius (nose R) (no sign)

r Wear (no sign)

X

2

7

3

6 1

0

8

5

4

Z

r

R

3

Tool nose point

(Note) The incremental value/absolute value setting mode changeover follows the tool length data setting

mode for R, and the tool wear data setting mode for r.