3. Tool Offset (L system)

3.2 Tool Length Data

I-94

Refer to "3 (II). Tool Offset (M system)" for M system.

6) Measure tool compensation amount with sensor contact

Approach the tool nose to the sensor with manual or handle feed.

Stop the feed when the tool nose contacts the sensor.

The tool length offset amount will be automatically calculated from the contacted position, and will be

stored in the tool length memory.

After measuring, the wear amount of the designated compensation No. will be cleared.

Note) The sensor contact surface is judged by the NC according to the manual axis movement

direction, so measure the tool compensation amount one axis at a time. The direction of the

axis movement when the sensor contacts the tool will be output to R90 (R290).

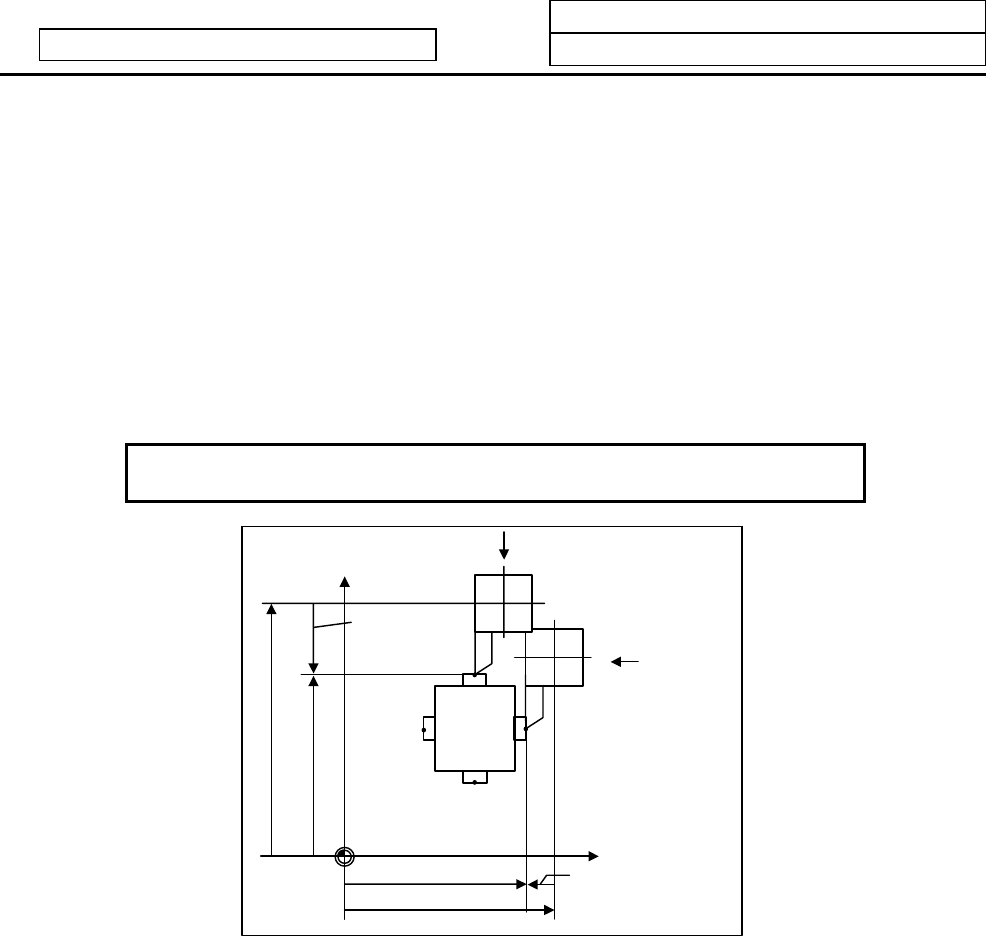

<Details of automatic calculation expression>

The tool compensation amount is automatically calculated with the following expression.

Tool compensation amount

= Machine coordinate value – Measurement basic value

Zaxis

X

axis tool

compensation

amount

X

axis

Turret

Xm

Zm

Z axis tool

compensation

amount

Machine value

Machine value

Turret

Tool compensation amount calculation diagram

7) Retract the tool.

8) Set the tool compensation amount for the X axis and Z axis using steps 5) to 7).

9) Repeat steps 5) to 8) for the required tools.

10) Turn the tool measurement mode signal OFF.

This completes the measurement of the tool compensation amount.