4. Absolute Position Detection System

4.3 Starting up Absolute Position Detection System

III-23

(b) Marked point alignment method

The handle or jog is operated to align the axis with the basic point of the machine.

Before performing zero-point initialization, specify the following parameter of the [ABS. POSI

PARAM] screen (for details, see Alarm/Parameter Manual):

#2050 absdir

[Operation procedure]

Operation procedure STATE display

1. Select the "ABS. POSITION SET" screen.

2. Select the handle mode, handle axis or jog mode.

3. Ensure that the origin point alignment method is applied for

the axis for which zero-point initialization is to be performed.

("TYPE" of [ABS. POSITION SET] screen indicates

NO-STOPPER

. )

• NG

if the absolute position is

lost.

• OK

if the absolute position

has been established.

4. Specify "1" to "#0 INIT. SET" for the axis for which zero-point

initialization is to be performed.

5. Specify data for "#2 ZERO".

6. Move the axis to the machine basic position and align it with

the basic point.

7. Specify "1" to "#1 ORIGIN".

ORIGIN SET

8. The machine will move in the direction specified with [ABS.

POSI PARAM] "#2050 absdir".

ORIG-RTN

9. The axis automatically stops at the first grid point.

• The basic machine coordinate system is automatically

set.

This sets up the absolute position.

10. This completes zero-point initialization.

After completion of zero-point initialization for all axes, turn

power OFF and ON again.

OK

11. Output parameter tape.

To change just the basic machine coordinate zero point, perform steps 4 and 5 above, and then turn the power

OFF and ON.

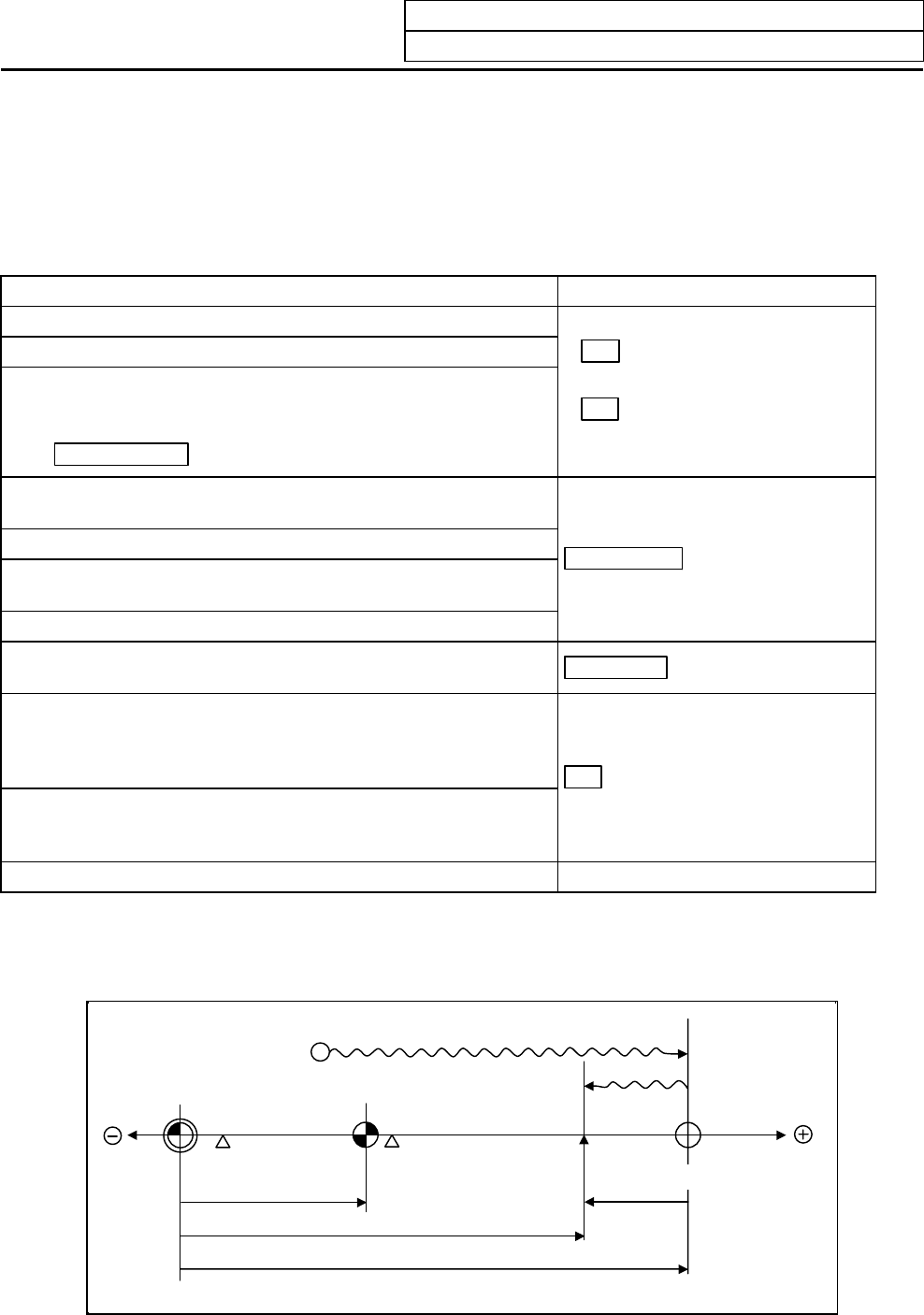

Zero point of basic

machine coordinate

Reference point

Zero-return parameter

"#2037 G53ofs"

Grid point

"#2 ZERO" (#2059 zerbas=1)

•

Select either "#2 ZERO" with the parameters.

"#2 ZERO" (#2059 zerbas=0)

Start point

Machine basic

point

"TO END"

6)

7)

8)9)

(Electrical basic position)

Zero-point initialization by origin point alignment method