6. Operation Panel Switch Functions

6.16 Deceleration Check

II-35

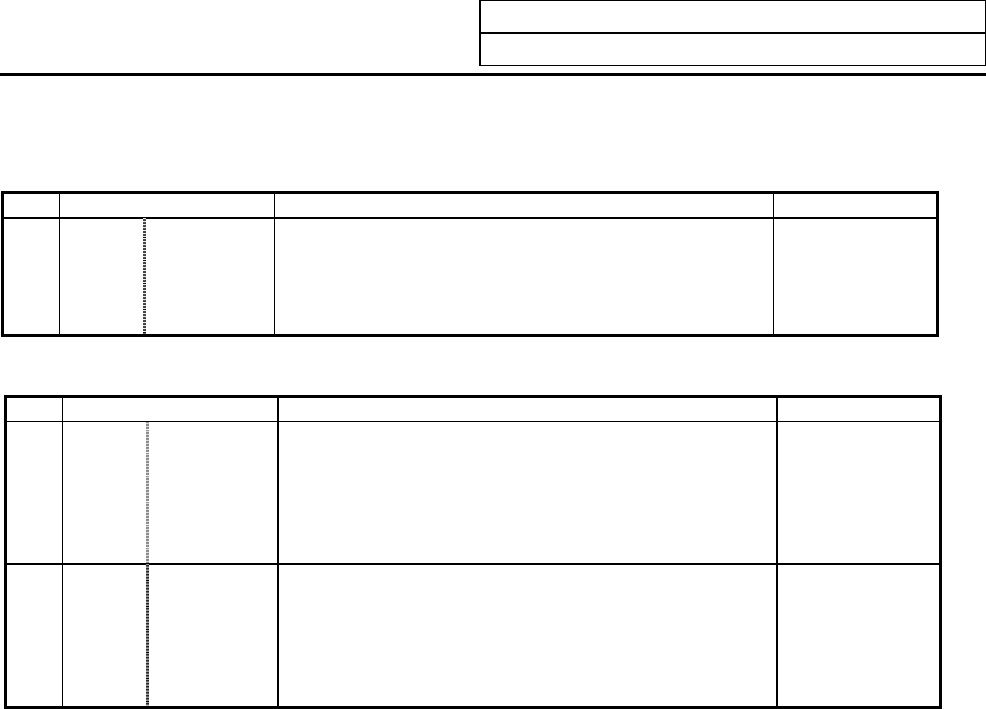

(3) Designation of in-position check width

(a) Servo parameter

# Items Details Setting range

2224 SV024

INP

In-position

width

Set the in-position detection width value.

Set the accuracy required of the machine.

The positioning accuracy increases when the setting

value is lowered, but the cycle time (settling time) will

increase. Set "50" for ordinary operation.

0 to 32767 (µm)

(b) Axis specification parameter

# Items Details Setting range

2077 G0inps G0

in-position

width

Specify the G0 in-position width (each axis) when an

in-position check is performed separately for G0 and

G1. (SV024 or this parameter, whichever is larger, is

applied.)

The standard value is 100 (50 µm). Value 0 indicates 1

µm. (Applied only for SV024)

0 to 32767

(in 0.5 µm steps)

2078 G1inps G1

in-position

width

Specify the G1 in-position width (each axis) when an

in-position check is performed separately for G0 and

G1. (SV024 or this parameter, whichever is larger, is

applied.)

The standard value is 100 (50 µm). Value 0 indicates 1

µm. (Applied only for SV024)

0 to 32767

(in 0.5 µm steps)

6.16.5 Precautions

(1) Designating deceleration check

• When in-position check is valid, set the in-position width in the servo parameters.

(2) Deceleration check for opposite direction movement reversal

• When deceleration check is valid (G0Ipfg=1), deceleration check will be executed when the axis

reverses its movement to the opposite direction at the G1

→

G0 successive block regardless of

whether G0 non-interpolation is ON or OFF.

• When deceleration check is valid (G0Ipfg=1), deceleration check will be executed when the axis

reverses its movement to the opposite direction at the G1

→

G0 successive block even in the fixed

cycle.

• In the G1

→

G28, G1

→

G29 or G1

→

30 successive blocks, deceleration check will always be

executed when the G1 movement is completed, when movement to the intermediate point is

completed and when movement to the return point is completed. Note that if the base specification

parameter simple zero point return (#1222 aux06/bit7) is valid, the base specification parameter G1

→

G0 deceleration check (G0Ipfg) will be followed when the G1 movement is completed and when

movement to the intermediate point is completed. (Deceleration check will always be executed when

movement to the return point is completed even in this case.)

(3) Designating in-position width

• The in-position width (programmable in-position check width) designated in the machining program has

a priority over the in-position width set in the parameters (SV024, G0inps, G1inps).

• When error detect is ON, in-position check will be forcibly carried out.